With forty years’ experience in the design, manufacture and specification of portable climate control equipment our origins can be traced back to the introduction of dehumidifiers to the UK back in the late 1970s. These days our range also includes commentary equipment such as large fan heaters, portable air conditioners, ventilation fans and portable boilers, however it is the humble dehumidifier where it all started.

Commercial dehumidifiers are electrical devices used to reduce and maintain the amount of moisture in the air known as humidity. The benefits of this include increased comfort, preservation of artefacts, speeding up construction processes and even personal health.Dehumidifiers can also help alleviate the musty smells and mildew associated with an excess of humidity. These versatile machines come in a number of forms and can be used for domestic, commercial and even industrial applications. Some of the most common applications are for drying plaster on building sites, helping to dry out flooded premises after the water has subsided and to prevent condensation in homes whilst larger units can usually be found at indoor ice rinks, swimming pools, storage warehouses and manufacturing plants.

A Brief Overview

Dehumidifiers will pass air through them and across a medium designed to extract the moisture from the air before returning it to the room and they come in two main type: Refrigerant dehumidifiers and dessicant dehumidifies.

Refrigerant dehumidifiers use the same vapour compression refrigeration cycle as a portable air conditioning unit to extract the water. The extracted water, which is know as condensate and a type of grey water, is usually collected in some form of tank or bucket or pumped away to a drain. The collected water is not generally suitable for human consumption but it can be used for a variety other processes. However, some dehumidifiers can be supplied with a reverse osmosis filter which will turn the condensate into potable water.

Desiccant dehumidifiers, which are also known also as absorption dehumidifiers are much less common. To extract the moisture dessicant units will pass the air across hydrophilic materials such as silica gel. Cheap domestic units might be available using single-use hydrophilic substance cartridges, gels, and powders while the larger commercial units can contain hot air recovery systems in order to remove humid air from outside the room in which they are being used.

The energy efficiency of dehumidifiers can vary widely.

Thermal condensation dehumidification

These methods use a cold surface to remove the moisture from the air. As the saturation vapor pressure of water decreases with decreasing temperature, the water within the air condenses on the surface, thereby separating it from the air.

Refrigeration dehumidification in more detail

Electric refrigeration dehumidifiers are by far the most well known type of dehumidifier. Using a fan to drive the air, they will pass it across a refrigerated heat exchanger where the moisture will condense and be collected. Also known as evaporators, there are 3 main types of heat exchanger used for dehumidification; coiled tube, fin and tube, and microchannel technology.

Following the moisture removal the air is then passed across another heat exchanger known as the condenser where it is heated and returned to the room. As a process dehumidification is much effective in environments with a higher ambient and high dew point, while performance will be restricted at lower temperatures.Greatest efficiency will be achieved with ambient temperatures above 20 °C with a relative humidity value of 45%. As relative humidity is determined using both dry bulb and wet bulb measurements the 45% figure will increase as the temperature decreases.

Unlike a portable air con unit a dehumidifier will not duct the heat generated by the vapour compression refrigeration cycle away, therefore any electric power used by the dehumidifier will stay within the room as heat, gently warming it in exactly the same way as an industrial electric fan heater of the same power would do.

Thanks to the process of latent heat of vaporisation, any water condensed within the room will also release the amount of heat needed to evaporate it back into the room. In effect, the process of using a dehumidifier within a room is the opposite of using an evaporative cooler, in that it removes water and adds heat rather than add moisture and remove heat. Thanks to this a portable dehumidifier, or any other type will always warm the room as both a part of and a byproduct of the process.

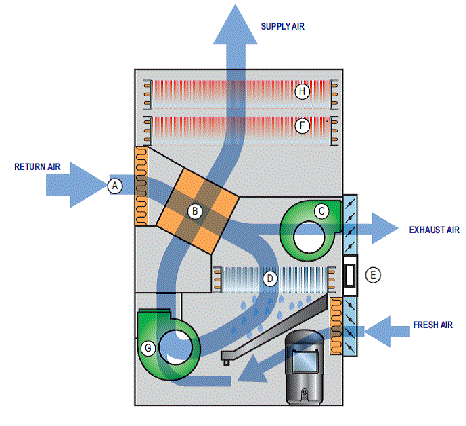

Warm, moist air is drawn into the unit at A in the diagram above. This air passes into a crossflow plate heat exchanger (B) where a substantial proportion of the sensible heat is transferred to a cool supply air stream. This process brings the extracted air close to saturation. The air then passes to the plenum chamber of the extract fan (C) where a portion of it may be rejected to outside. The amount that is rejected can be varied and is determined either by legislation on fresh air requirements, or by the requirement to maintain a fresh, odour free environment. The balance of the air then passes into the evaporator coil of the heat pump where it is cooled and the moisture is condensed. This process yields substantial amounts of latent energy to the refrigeration circuit. Fresh air is then introduced to replace the amount that was extracted and the mix is discharged by the supply fan (G) to the crossflow plate exchanger (B) where it is heated by the extract air from the pool. This pre-warmed air then passes through the heat pump condenser (F) where it is heated by the latent energy removed during the condensation process as well as the energy input to the compressor. The warm dry air is then discharged to the room

Air conditioning units

Portable air conditioning units or fixed air conditioning systems share many components and both utilize a vapour compression cycle refrigeration system and as such an air conditioner will dehumidify the air as part of the cooling process. The primary difference between the two though are that as soon as the air is passed across the evaporator in an air unit it is returned to the room, whereas with a dehumidifier the air is passed across the condenser for reheating prior to being discharged back into the room. With a portable air conditioner additional energy will be required to exhaust the heat either by means of a fan and ducting or with a split system to pump the refrigerant to the condenser unit, where an additional fan will again be used.

Spray Dehumidifiers

Sometimes called air washers spray dehumidifiers will combine sprays of cooled water and air to capture the moisture within the atmosphere. This format of dehumidifier works because water that is cooler than atmospheric dewpoint allows atmospheric water to condense to it fast than water evaporates from it. This type of unit will also capture airbourn pollutants such as dust and pollen, hence the alternative name.

Thermoelectric dehumidification

Thermoelectric dehumidifiers use something called Peltier heat pump that cools a surface which then causes moisture held within the air to condense on said surface. Thermoelectric dehumidifiers are a much simpler type of machine which, thanks to the lack of mechanical compressor, are also much quieter than refrigerated dehumidifiers and has the benefit of being quieter compared to a dehumidifier with a mechanical compressor. Thermoelectric dehumidifiers do however suffer from a comparatively poor Coefficient of Performance, which mean they’re only really suitable as mainly as small dehumidifiers.

Ice Build up

Under certain conditions of temperature and humidity, enough ice may form on a refrigeration dehumidifier’s evaporator coils that can’t be cleared by the defrost cycle causing an ice build up that can restrict airflow, reduce performance and in extreme cases even permanently damage the unit. One particularly effective way to reduce the risk of this is to run an industrial electric fan heater with the dehumidifier to increase the ambient temperature within the environment you are trying to dehumidify.

Dessicant dehumidifiers

Dessicant dehumidifiers expose air to a special humidity-absorbing material called a desiccant, such as silica gel. Once moisture laden this material, or ‘dessicant’ as it is also known is then moved to moved to a separate part of the machine where it heated to dry it out, this second process is generally called “recharging”. The desiccant is usually housed on a sort of wheel which as it rotates moves between the dehumidifying and recharging sections of the unit.

Dessicant dehumidifiers are particularly well suited to environments with high humidity levels at low temperatures. They are commonly used in areas of industry where very low relative humidity levels are required as <35% can be achieved easily.

Dehumidifiers that utilise the absorption principle instead of refrigeration to remove moisture are generally quieter as they don’t use a compressor. They are also more effective at lower temperatures as refrigeration coils used for dehumidification lose efficiency the colder the ambient gets.

Condensate

Disposal

Some portable dehumidifiers, especially those designed for domestic applications,will come complete with a vessel for condensate collection. To prevent overfill and subsequent spillage these vessels will usually have some sort of float sensor to switch the unit off once it is full.When used in warmer, more humid environments these buckets willfill more quickly than in colder, drier climates and will need to be manually emptied and replaced several times per day to ensure continued operation.

Portable commercial dehumidifiers tend to have a spout leading from the drip tray that sits under the evaporator coil and catches the condensate from the coil above. A hose can then be attached to the spot and fed directly to a suitable drain point. Alternatively, some units may feature a condensate pump to move collected water to a disposal location when gravity drainage is not possible.

Potability

Although classified as a type of clean grey water the condensate produced by dehumidifiers is not considered safe for either human consumption or watering vegetables, though it can be used for watering plants. The primary concerns are:

- The water may contain trace metals from solder and other metallic parts, most significantly lead (which is quite dangerous), but also copper, aluminium, or zine. The trace metals may pose a danger if used on edible plants, as they can bioaccumulate. However, the water is usable for irrigation of non-edible plants.

- Various pathogens, including fungal spores, may accumulate in the water, particularly due to its stafnancy. Unlike in distilled water production, the water is not boiled, which would kill pathogens (including bacteria).

- As with distilled water, beneficial minerals are largely absent.

Applications and common uses

Homes and offices:

Dehumidifiers used within buildings can help control and maintain:

- Excessive body perspiration build up that cannot evaporate in moisture-saturated air

- Condensation dripping from cold-water pipes

- Warping and sticking of furniture and doors

- Mold and mildew, which can cause fabrics, books, and furnishings to develop mustiness

- Clothes moths, fleas, cockroaches, woodlice, millipedes, and dust mites which thrive in damp conditions (basements, crawl spaces, kitchens, bedrooms, bathrooms, spas or indoor pool areas, warehouses, workshops)

Building sites and construction

Commercial dehumidifiers are also commonly used within the construction industry and renovations of indoor space to remove excess humidity or mildew. The can help with the curing of plaster, paint and other finishing materials.

For details on our full range of dehumidifiers, portable air con, large industrial fan heaters, cooling fans, ventilation fans, fan coil units and portable packaged water boilers please visit call or email us and a member of our expert team will be able to assist. Alternatively you can also find comprehensive information on our website.