There is a huge choice of industrial fan heaters and fan blow heaters available on the market, so if you’re considering purchasing one then its well worth taking a moment to gain a little understanding of the basics as that will enable you to narrow the selection and make your choice that bit easier. On this page we take a look at;

- Applications

- Expectations and Perceived Faults

- Heat Output

- Voltage

- Quality

- Fixed or Mobile

- Ductable or Not Ductable

- Thermostats

- Control Stages

- Output Temperature and the Delta T

- Electric Power in vs. Heat Out

- Plugs, Sockets and Leads

- Running Costs

Applications For Industrial Fan Heaters

Electric industrial fan heaters are usually supplementary heating and not the primary heat source in the workplace. Typically this is because the main heating lacks capacity in the coldest weather, doesn’t quite reach some parts of the building or is no longer quite as suitable as it was at point of installation, therefore people bring in industrial fan heaters or infrared heaters to make up the short fall and keep everyone warm. However, there are some instances where a lack of mains gas or centralised heating system can force companies to use electric industrial fan heaters as their principle heat source. In instances such as these though it should be born in mind that, despite their effectiveness, versatility, relative low-cost and ease of installation electricity isn’t normally the cheapest fuel to use to heat in an industrial application.

Expectations And Perceived Faults With Industrial Fan Heaters

We include this little section to help avoid some of the occasional misunderstandings that can arise in the industrial fan heater market;

• There have been instances where someone purchases an industrial fan heaters as they believe it will deliver more heat than a domestic heater. A 2kW industrial heater from us will not give you anymore heat than a 2kW domestic heater from Amazon, which can lead to complaints along the lines of ‘this heater does not produce any more heat than the fan heater in my home, therefore it is defective’. It is a difficult process explaining that as both heaters are probably 2kw then the heat outputs will be of a similar scale. The difference between the two is usually build quality and materials. Our Fireflo industrial heaters are made from tough steel bodies rather than cheap moulded plastic so they’re able to withstand industrial use, and most of them are made at our factory in Redditch, England rather than the far east, unlike cheap domestic fan heaters.

• The other misguided expectation is that the heat will come out as soon as you switch the industrial fan heater on. Industrial fan heaters have much heavier elements and greater airflow’s than domestic fan heaters so it takes them a little bit longer to get up to temperature, sometimes about 5 minutes or so, before the operating temperature is reached.

• Because the elements in industrial fan heaters have a relatively large thermal mass, switching them off might seem to have no effect as the fan keeps going. This is called overrun and is standard feature of most of our industrial fan heaters, especially the large three phase units. It is a safety feature designed to dissipate the excess heat load, protect the machine and prolong the life of the elements prevent the electrics from getting too hot, and reduce the possibility of it becoming a fire hazard. Once the heater has been switched off the power to the elements will be cut but the fan will continue to run until either a preset low delivery temperature has been reached. If it does not overrun then it has a fault!

Heat Output

The first stage of establishing what size industrial heater you need is to determine how much heat is required. To help with this we have developed a simple to use heat calculator

The heat calculator provides uses common ‘rules of thumb’ and our extensive experience to approximate heating requirements, which is accurate enough for 99.99% of day to day enquiries. If your application is a little more specialist then feel free to contact one of our expert team on 01527 830610.

For accurate heat loss calculations you would need work it out from scratch using accurate values of the various materials, orientation, people and machines within your room or building. Bear in mind the heat contribution that might be made by other heating in the room, whether it is from a heating system or perhaps from a hot industrial process or machine. If it is a variety of rooms, in other words the heater will be used in several different places, then try to select the largest amount of power that you may need, bearing in mind that the larger industrial fan heaters can become quite heavy and difficult to move about and it maybe better to sacrifice some heating power in favour of portability. Alternatively, if you’re looking at something like 200kW of heat, which just isn’t practical, then a good alternative could be to use infrared heaters positioned around the room or area and directed at staff. As infrared heaters only heat solid objects rather than the air they are often highly suited to large, sparsely staffed places such as distribution warehouse or MOT bays at a car dealership where the main doors might be open for most of the day.

Fan Heater Voltage

Your electrical supply will determine which industrial fan heater options are available to you. Very basically (and not quite true) the lower the voltage the more limited the potential heat output.

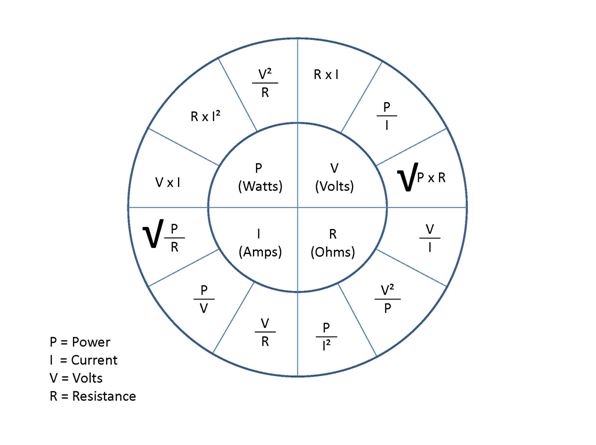

Ohms law states that watts = volts x amps. (See diagram below) which means if you have a 110v supply running from a 16 Amp transformer, then the maximum power you can deliver is 1760 watts – not a lot. This is why 110v fan heaters are typically connected to a 32 amp transformer where the maximum power delivery is a theoretical 3520 watts. Even this, say with a safety margin, means that the heaters connected to a 110v supply are typically going to be no more than 3kw.

The standard 230v single phase socket on a wall is limited to 13A. But because there may be half a dozen sockets that your heater is not plugged into fans heaters are generally designed to draw no more than a nominal 3kw (nominal because power generation isn’t constant and the voltage can fluctuate therefore affecting the current so for safety most ‘3kW heaters’ will actually be closer to 2.6-2.8kW. This a safety margin to accommodate higher current draw cause by the voltage fluctuations).Although 230V suppliers are fairly commonly available all the way up to 32A, Generally 230v heaters will be no more than 3kw.

Our higher power fan heaters need to be connected to a 400v 3 phase supply. Indeed the choice and capability of not only industrial fan heaters but most HVAC equipment including heaters, air conditioning, air curtains etc. dramatically increases when 3 phase supply is available, because remembering Ohms Law, not only is the voltage larger and 3 phases but the current limits can also be much larger than is the case for 110v and 230V.

Quality of Industrial Fan Heaters

The old adage ‘buy cheap, buy twice’ is as true for industrial fan heaters as for any other product. The smaller industrial fan heaters on the market are largely dominated by branded clones. That is, they are made in a factory somewhere in the far east with a colour and brand to match the importers requirements. Before parting company with your money on the cheapest ‘industrial’ fan heater you can find, please consider how important it is that the heater lasts good while after the warranty has expired and that spares can be obtained with ease, e.g. a new set of elements or fan. It’s also worth bearing in in mind that even though a heater might look the same as another one but it’s a bit more expensive then there’s probably a good reason for that. As with everywhere else in the world you can get well made items from China and not so well made one’s and the most obvious difference is usually the price, so if you want something that might fall apart after a couple of weeks then buy the cheapest, but be prepared to buy another one pretty soon.

We do have some clone models of in our range as there is a market for them. The difference with ours though is that because we’ve been manufacturing our own equipment for two generations we’re acutely aware of what’s needed of a genuine ‘industrial’ product and therefore we only supply our equipment that we’d put our name on, anything we import has been inspected by our own engineers and independently verified by a specialist test house such as TUV or Intertek.

Fixed Or Mobile Industrial Fan Heater

Whist the smallest industrial fan heaters are usually free-standing units that can be easily carried from one room to another, larger heat requirements can often be delivered from fan heaters installed on brackets mounted to walls or columns, or even slung from the roof support or ceiling structure. The choice of mobile or fixed format depends on whether the unit is for spot heating or for general heating. If for general heating then there is an advantage to having the heater supported of the wall and indeed heaters mounted in this way in smaller buildings can induce sufficient circulation within the room to prevent stratification (i.e. where the heat rises and is static under the ceiling)

Electric industrial fan heaters that are designed for wall mounting tend to have quite lightweight casings; the reasoning being that if the heater is on a bracket out of reach then it does not need to be resistant to the same level of bumps and knocks that a free-standing unit has to endure. Even with lighter casings there is no reason why a wall mounted fan heater should not provide many years of service. They may need a new element or fan from time to time, but the casings, even though light weight, generally outlast the heater.

Here at Broughton our FireFlo range of portable industrial fan and infra red heaters are designed specifically to withstand the knocks and abuse of daily site use as portable heaters, there have been applications where users have been mounted on walls using dedicated brackets.

In higher output electric industrial fan heaters ‘mobility’ takes on a slightly different meaning. Some of the 3 phase heaters that we offer are very large and heavy and although they can be pushed about on casters they cannot be lifted without the aid of a forklift or other lifting gear. To accommodate this the FF42, for example, comes with heavy-duty braked casters, lifting eyes and forklift pockets.

Ductable Or Not Ductable Industrial Fan Heater

If you only need to deliver heat into the room where space heating is required then it is an easy choice; you don’t need an industrial fan heater with a duct spigot on the front. If you need a fan heater to deliver heat into a separate room, building, enclosed space or even onto part of a production process, then you need a ductable fan heater.

Our FireFlo heaters can have a round spigot on the front for connection of flexible ducting and also that it will be equipped with a fan that is capable to delivering air along a length of flexible ducting without running out of puff. Flexible ducting, because it is corrugated (i.e. bumpy) inside, presents a considerable resistance (compared to smooth bore ducting) to moving air therefore to overcome this resistance the heater fan has to have sufficient pressure capability, something not offered by cheaper imported or ‘clone’ heaters.

Ductable industrial fan heaters need to selected for the heat output and the flow/pressure capability of the be fan. Most of our ductable models state what length of duct can be used with the heater, and on some models this can be as long as 10M.

Industrial Fan Heater Thermostats

The usual understanding of ‘thermostats’ is a device to regulate the heating operation according to the requirement of the ambient air temperature. However, caution is required. In recent years, some heaters have been offered as having a thermostat, when in fact they don’t. The confusion arises when thermal overload devices in the heater are miss-described as thermostats, leading people to purchase them believing that they offer a high level of control. All our electric fan heaters have thermal overload protection, to offer them without would be unsafe we feel.

All fan heaters in our range have ‘on board’ thermostats as standard, whilst others can have remote thermostats as well for when the unit needs to stand outside the area to be heated. They can also come in useful when people want to wall mount the units.

Over the years we have also been asked to supply thermostats that control heat based on several steps (2 step, 3 step etc.) usually based around the number of elements in the heater that can be separately fired up, which depends on if they are wired in star or delta. This functionality can either be offered by one sophisticated device or by several basic devices preset to different temperature settings and operated by a single device.

Industrial Fan Heater Control Stages

A 42kW industrial fan heater with a single speed fan and single heat output doesn’t really offer enough versatility. Control is important for most applications, sometimes once an environment reaches the desired temperature you might want to reduce the output to hold it rather than have the heat switch off altogether, cool down, then come on again. Alternatively, if it’s just a bit too cold rather than freezing then you might just want a bit of heat so it’s better to have a couple of settings It is useful to have a number of fan stages as well as heat stages, as well as the ability to use the machine on ‘fan only’ is a summer bonus. Most of the heaters we supply have 2 or 3 heat stages so you can tailor the output to suit.

Output Temperature and the Delta T

Delta T (sometimes shown as ∆T) is the difference in temperature between the air going into the unit and the temperature of the air coming out.It varies from heater to heater and indeed in any one heater it dependson the heat and fan settings where applicable, however where a fan heaters specification states a delta T (sometimes abbreviated to ∆T) it means at the maximum heat and maximum air flow. It is typical of industrial fan heaters to have a ∆T of between 40 and 55°C. On our FFHT32 and FFVH32 you can obtain a delta T of 55°C to 90°C which also feature a range of thermal overload protection that will switch off the elements.

Plugs, Sockets and Leads for Heaters

Single phase industrial fan heaters come complete with a length of cable and a suitable fitted plug , and in the case of 110V would be a round 3 round pin plug in either 16A or 32A, for fitting into a transformer. With 3 phase heaters there are a greater variety of plugs depending on the current and if there’s a neutral, earth or both needed .

While some of the smaller three phase heaters do come with a cable and plug others don’t (which comes from the belief that what ever plug was fitted it would be the wrong one). There is a generally held assumption with larger 3 phase equipment that they should be hard wired to a supply and therefore it is typical for such heaters to be equipped with a connection block but no lead. An alternative to connection block is a CEE connection socket, which is a socket but built into the heater.

For more advice or details on the FireFlo range of industrial electric fan heaters, infra red heaters, portable air conditioning units, dehumidifiers, evaporative coolers, portable electric boilers and ventilation fans please feel free to call us on 01527 830610 or email us on sales@broughtoneap.co.uk, where a member of our expert team will be able to help you with any questions you might have.