Among our range of portable cooling equipment is the Comcool evaporative cooler, but what is evaporative cooling? How does it work and what are the differences between this process and traditional air conditioning?

See our full range of portable air conditioners here

Evaporative coolers, also referred to as swamp coolers, swamp boxes, desert coolers, and wet air coolers, utilise the process of water evaporation to extract heat from warm, arid air. This method of cooling contrasts with conventional portable air conditioning systems, which employ vapour-compression or absorption refrigeration cycles. Evaporative coolers exploit water’s significant enthalpy of vaporisation, meaning it absorbs a considerable amount of heat during evaporation. Through this mechanism, dry air’s temperature can be notably decreased as liquid water transitions to water vapour, which is essentially evaporation. One of the primary advantages of evaporative cooling is its energy efficiency compared to refrigeration. Additionally, in extremely dry climates, evaporative air cooling can increase relative humidity by introducing moisture into the air, thereby fostering a more comfortable indoor environment.

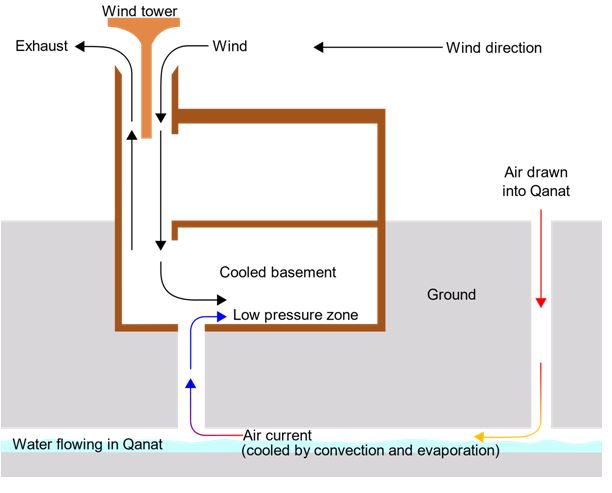

Evaporative cooling is an age-old technology with roots tracing back to ancient Egypt and Persia, as documented by historical records. These ancient civilisations ingeniously utilised a basic form of evaporative cooling known as the ‘windcatcher.’ These structures featured wind shafts positioned atop buildings, which captured and directed wind over water in underground channels called qanats. This process effectively mitigated the desert heat before releasing cooled air into the buildings. Although the methods have evolved over time, modern evaporative cooling techniques, notably prevalent in Iran, now incorporate fans and cooling pads instead of the traditional wet curtain method.

The essence of evaporative cooling lies in the transformation of liquid water into vapor or steam using the thermal energy present in the air, resulting in a reduction in air temperature. This process entails the extraction of energy, known as sensible heat, from the air to facilitate water evaporation. This energy is then converted into latent heat, which is stored within the water vapor component of the air, while maintaining a constant enthalpy value. This conversion, termed as an isenthalpic process, leads to a proportional drop in air temperature corresponding to the decrease in sensible heat and an increase in humidity proportional to the latent heat gain. Understanding evaporative cooling’s intricacies can be aided by visualising it through a psychrometric chart, which illustrates the journey from initial air conditions to a state of higher humidity.

A natural example of evaporative cooling is perspiration, where sweat evaporating from the body aids in cooling. The rate of heat transfer through evaporation depends on factors such as temperature and humidity. For each kilogram of water vaporised, a substantial amount of energy is transferred, highlighting the effectiveness of this process. Evaporative cooling finds application in various contexts, from simple evaporative coolers evaporating water into the environment to complex systems used in interior space cooling units.

Evaporative cooling thrives in environments with low relative humidity, making it particularly popular in desert climates like Iran and Egypt. However, it’s crucial to consider typical climate data when assessing its potential effectiveness, focusing on parameters such as dry-bulb temperature, wet-bulb temperature, and wet-bulb depression. While evaporative cooling is well-suited for hot, dry climates, its efficacy may be hindered during short periods of high humidity, such as during monsoon seasons.

In regions with moderate humidity, portable evaporative cooling presents a cost-effective alternative to industrial portable air conditioning units, finding applications in various settings such as industrial plants, warehouses, commercial kitchens, and even battery farming centres. However, its thermal comfort benefits in highly humid climates may be limited to increased ventilation and air movement rather than significant temperature reduction.

Other examples of Evaporative Cooling and Coolers

Trees play a vital role in the environment by releasing large amounts of water through tiny pores in their leaves known as stomata. This process, called transpiration, facilitates evaporative cooling and influences climate patterns both locally and globally. Simple yet ingenious devices like evaporative cooling chambers (ECCs) and clay pot coolers, also known as pot-in-pot refrigerators, offer affordable and energy-efficient solutions for preserving vegetables without relying on electricity. Many regions with hot and arid climates, such as North Africa, the Sahel, the Horn of Africa, southern Africa, the Middle East, arid parts of South Asia, and Australia, stand to benefit from evaporative cooling technologies. For rural communities in these areas, evaporative cooling chambers can significantly reduce post-harvest losses, decrease travel time to markets, save money, and increase the availability of fresh produce for consumption.

Evaporative cooling finds widespread use in cryogenic applications, where maintaining extremely low temperatures is essential. By continuously evaporating cryogenic liquids like helium, cryocoolers and cryostats can achieve temperatures as low as 1.2 K or even below 300 mK. These techniques are vital components of scientific research and technological advancements in fields requiring ultra-low temperatures.

Furthermore, evaporative cooling serves as a crucial step in achieving the ultra-low temperatures necessary for Bose–Einstein condensation (BEC). Through forced evaporative cooling, high-energy atoms are selectively removed from an atom cloud until the remaining cloud reaches the BEC transition temperature, typically around 1μK for a cloud of 1 million alkali atoms.

In space exploration, manned spacecraft utilise evaporative cooling systems alongside other thermal control methods like thermal radiation. Craft such as the Space Shuttle and the Apollo spacecraft incorporate evaporative cooling mechanisms to regulate temperatures effectively in the vacuum of space. These systems, including radiators and sublimators, demonstrate the versatility and efficiency of evaporative cooling in extreme environments.

Designs

Evaporative coolers leverage the high enthalpy of vaporization of water, making them significantly more energy-efficient than vapour-compression or absorption air conditioning systems. While direct evaporative coolers may increase relative humidity to uncomfortable levels in certain climates, indirect and two-stage evaporative coolers offer solutions to maintain comfortable humidity levels while harnessing the benefits of evaporative cooling.

Direct evaporative cooling

Direct evaporative cooling (open circuit) serves to decrease the temperature and raise the humidity of the air by utilising the latent heat of evaporation, transforming liquid water into water vapour. This process maintains the energy level of the air, converting warm dry air into cooler moist air. The outside air’s heat is employed to evaporate water, resulting in an increase in relative humidity (RH) to 70 to 90%, which diminishes the cooling efficacy of human perspiration. To prevent saturation and halt evaporation, the moist air must be continuously discharged outside.

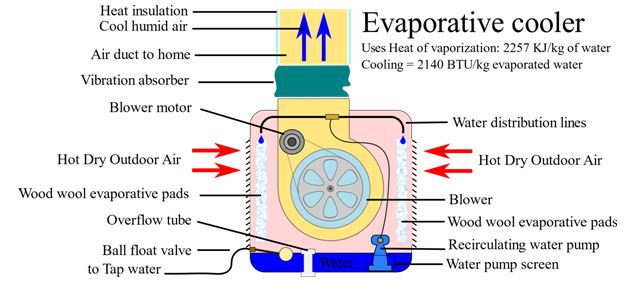

A mechanical direct evaporative cooler unit operates by drawing air through a wetted membrane or pad, providing a substantial surface area for water evaporation into the air. Water is sprayed onto the top of the pad, allowing it to trickle down and keep the membrane consistently saturated. Excess water is collected in a pan at the bottom of the membrane and recirculated to the top. Typically compact, single-stage direct evaporative coolers consist of the membrane, water pump, and centrifugal fan. However, mineral deposits from municipal water can accumulate on the membrane, leading to clogging over time. Regular cleaning and maintenance are necessary for optimal performance, depending on mineral content and evaporation rate. Generally, exhaust of the supply air from single-stage evaporative coolers is required due to the high humidity of the supply air. Some design innovations have been proposed to utilise the air’s energy, such as directing exhaust air through double-glazed windows to reduce solar energy absorption. Compared to the energy needed for equivalent cooling with a compressor, single-stage evaporative coolers consume less energy.

Passive direct evaporative cooling can occur without the aid of a fan wherever evaporatively cooled water can cool a space. This can be achieved through fountains or architectural designs like the evaporative downdraft cooling tower, also known as a “passive cooling tower.” In this design, outside air flows into a tower constructed within or adjacent to the building, coming into contact with water either through a wetted membrane or a mister. As water evaporates in the outside air, it becomes cooler and less buoyant, creating a downward flow in the tower. Cooler air is then allowed into the interior through an outlet at the tower’s bottom. Similar to mechanical evaporative coolers, towers offer an energy-efficient solution for hot and dry climates, requiring only a water pump to raise water to the tower’s top. Energy savings from employing a passive direct evaporative cooling strategy depend on the climate and heat load. In arid climates with a significant wet-bulb depression, cooling towers can provide sufficient cooling during summer

conditions to achieve net zero energy consumption. For instance, a 371 m² (4,000 ft²) retail store in Tucson, Arizona, experiencing a sensible heat gain of 29.3 kJ/h (100,000 Btu/h), can be entirely cooled by two passive cooling towers providing 11890 m³/h (7,000 cfm) each.

The Zion National Park visitors’ centre, equipped with two passive cooling towers, achieved a cooling energy intensity of 14.5 MJ/m² (1.28 kBtu/ft²), which was 77% less than a typical building in the western United States, consuming 62.5 MJ/m² (5.5 kBtu/ft²). Field performance results from Kuwait indicated that the power requirements for an evaporative cooler are approximately 75% less than those for a portable air conditioning unit.

Indirect evaporative cooling

Indirect evaporative cooling (closed circuit) involves a cooling process that integrates direct evaporative cooling with a heat exchanger to transfer cool energy to the supply air. Unlike direct evaporative cooling, the cooled moist air doesn’t directly interact with the conditioned supply air. Instead, the moist air stream is expelled outside or utilised to cool other external devices like solar cells, which operate more efficiently when kept cool. Some indirect cooler manufacturers utilise the Maisotsenko cycle, employing an iterative (multi-step) heat exchanger that can lower the temperature of the product air to below the wet-bulb temperature, approaching the dew point where dew forms. Although no moisture is added to the incoming air, the relative humidity (RH) level increases slightly according to the Temperature-RH formula. However, the relatively dry air resulting from indirect evaporative cooling facilitates easier evaporation of inhabitants’ perspiration, enhancing the technique’s effectiveness. Indirect cooling proves to be an efficient strategy for hot-humid climates where increasing the moisture content of the supply air is impractical due to indoor air quality and human thermal comfort concerns. The following graphs illustrate the direct and indirect evaporative cooling processes, depicting changes in temperature, moisture content, and relative humidity of the air.

Passive indirect evaporative cooling strategies are uncommon because they involve architectural elements acting as heat exchangers (e.g., roofs). These elements can be sprayed with water and cooled through water evaporation, but such strategies are rare due to high water consumption, which poses the risk of water intrusion and compromising building structure.

Two-stage evaporative cooling, or indirect-direct

In the first stage of a two-stage cooler, warm air undergoes indirect pre-cooling without adding humidity by passing through a heat exchanger cooled by evaporation on the outside. In the direct stage, the pre-cooled air passes through a water-soaked pad, picking up humidity as it cools. Since the air supply is pre-cooled in the first stage, less humidity is transferred in the direct stage to achieve the desired cooling temperatures. Manufacturers claim that the result is cooler air with an RH between 50-70%, depending on the climate, compared to a traditional system that produces about 70–80% relative humidity in the conditioned air.

In a hybrid design, direct or indirect cooling is combined with vapour-compression or absorption air conditioning to enhance overall efficiency and/or reduce the temperature below the wet-bulb limit.

Materials

Traditionally, evaporative cooler pads consist of excelsior (a type of wood wool made primarily from aspen wood fibre) inside a containment net, but more modern materials like plastics and melamine paper are increasingly used as cooler-pad media. Modern rigid media, typically 200MM or 300MM thick, retains more moisture, cooling air more effectively than the usually much thinner aspen media. Corrugated cardboard has also been occasionally used as cooling media in evaporative coolers.

Design considerations

Water use

In arid and semi-arid regions, water scarcity is a critical concern in cooling system design. For instance, at the Zion National Park visitors’ centre, approximately 420,938 litres (111,200 gallons) of water were consumed in 2002 for the two passive cooling towers. However, experts argue that evaporative coolers use substantially less electricity compared to chillers, making their overall water usage comparable.

Shading

Direct solar exposure to media pads increases evaporation rates and water consumption. Prolonged sunlight exposure may also degrade cooling media and heat up other components of the evaporative cooler. Therefore, shading is advisable in most applications to mitigate these effects.

Mechanical systems

In both mechanical and passive applications of evaporative cooling, apart from fans, pumps are the only mechanical equipment required. Pumps are used either to recirculate water to wet media pads or to provide water at high pressure to a mister system for passive cooling. Pump specifications vary based on factors such as evaporation rates, media pad area, and cooler design. For example, the Zion National Park visitors’ centre employs a 250 W (1/3 HP) pump.

Exhaust

A continuous supply of fresh air is essential for effective evaporative cooling. Therefore, exhaust ducts or open windows must allow air to escape constantly from the air-conditioned area. Without proper exhaust, pressure builds up, hindering air movement through the media and into the conditioned area. Optimising the placement of cooled-air inlets and layout of house passages, doors, and room windows enhances the system’s effectiveness in directing cooled air. Continuous airflow must be maintained, ensuring that exhaust windows or vents do not restrict airflow. Consideration of outside wind direction is crucial, as strong winds can impede exhausted air. Therefore, it’s best to open downwind windows while closing upwind ones.

Different types of installations

Typical installations

Residential and industrial portable evaporative coolers typically use direct evaporation. They comprise an enclosed metal or plastic box with vented sides, equipped with a centrifugal or axial

fan or blower and a water pump to wet the cooling pads. Fixed installation units can be roof-mounted (down draft or downflow) or installed on exterior walls or windows (side draft or horizontal flow). These units draw ambient air through vents, cooling it by evaporating water from damp pads, and deliver the cooled, moist air into the building.

Evaporative (wet) cooling towers

Cooling towers are structures designed to cool water or other heat transfer media to near-ambient wet-bulb temperature. They operate on the evaporative cooling principle but are optimised for cooling water rather than air. Cooling towers can often be found on large buildings or industrial sites, transferring heat to the environment from various sources such as chillers or industrial processes.

Considering Broughton EAP Ltd’s expertise in manufacturing portable evaporative coolers, portable air conditioning units, industrial electric fan heaters, cooling, and ventilation fans, cooling towers hold relevance to their operations.

Misting systems

Misting systems operate by propelling water through high-pressure pumps and tubing, passing it through brass and stainless steel mist nozzles with tiny orifices of approximately 5 micrometres, creating a micro-fine mist. The minute water droplets produced evaporate instantly upon contact

with the air, a phenomenon known as flash evaporation. This rapid evaporation can lower the surrounding air temperature by up to 35 °F (20 °C) within seconds. Optimal cooling is achieved by mounting the mist line around 8 to 10 feet (2.4 to 3.0 m) above the ground for patio systems. Misting systems find application in various areas such as flowerbeds, pet areas, livestock facilities, kennels, insect and odour control, zoos, veterinary clinics, produce cooling, and greenhouses.

Misting fans

Misting fans function similarly to humidifiers, where a fan disperses a fine mist of water into the air. If the air is relatively dry, the water evaporates, absorbing heat from the surroundings and functioning as an air cooler. Misting fans are commonly used outdoors, especially in dry climates, but they can also be used indoors.

Portable battery-powered misting fans, comprising an electric fan and a hand-operated water spray pump, are available as novelty items. However, their effectiveness is often debatable.

Performance

The performance of evaporative cooling systems is influenced by factors such as external temperature and humidity levels. Ideally, a residential cooler should be capable of reducing the air temperature to within 3 to 4 °C (5 to 7 °F) of the wet bulb temperature.

Predicting cooler performance requires an understanding of psychrometrics. Since standard weather reports typically include dewpoint and relative humidity but not wet bulb temperature, a

psychrometric chart or computer program is necessary to compute the wet bulb temperature. Once the wet bulb temperature and dry bulb temperature are determined, the cooling performance, or leaving air temperature of the cooler, can be calculated.

For direct evaporative cooling, the direct saturation efficiency (ε) quantifies how close the temperature of the air leaving the cooler is to the wet bulb temperature of the incoming air. This efficiency can be calculated accordingly.

€ = ( Te,db – Tl,db ) / (Te,db – Te,wb)

€ = direct evaporative cooling saturation efficiency (%)

Te,db {\displaystyle T_{e,db}}TT = entering air dry-bulb temperature (°C)

Tl,db {\displaystyle T_{l,db}}T= leaving air dry-bulb temperature (°C)

Te,wb {\displaystyle T_{e,wb}}T= entering air wet-bulb temperature (°C)

Evaporative media efficiency typically falls within the range of 80% to 90%, indicating their ability to effectively cool air. The most efficient systems boast the capability to reduce dry air temperature to approximately 95% of the wet-bulb temperature, while the least efficient ones may only achieve around 50%. Interestingly, the efficiency of evaporation tends to remain relatively stable over time.

In residential evaporative coolers, the use of typical aspen pads offers an efficiency of approximately 85%. However, CELdek-type evaporative media, known for their superior performance, can achieve efficiencies exceeding 90%, contingent upon air velocity. As a result, CELdek media finds more frequent application in large-scale commercial and industrial installations.

For instance, consider Las Vegas, where a typical summer day presents a dry bulb temperature of 42 °C (108 °F) and a wet bulb temperature of 19 °C (66 °F), equating to roughly 8% relative humidity. In such conditions, a residential cooler with 85% efficiency would yield a leaving air temperature of approximately 22.45 °C or 72.41 °F.

To estimate performance accurately, two methods can be employed:

Utilize a psychrometric chart to compute the wet bulb temperature, then add 5–7 °F accordingly. Apply a rule of thumb suggesting that the wet bulb temperature equals the ambient temperature minus one-third of the difference between the ambient temperature and the dew point. Subsequently, add 5–7 °F as described above.

To further elucidate this relationship, consider the following examples:

At 32 °C (90 °F) and 15% relative humidity, air may be cooled to nearly 16 °C (61 °F), with a dew point of 2 °C (36 °F).

At 32 °C and 50% relative humidity, air may be cooled to about 24 °C (75 °F), while the dew point for these conditions is 20 °C (68 °F).

At 40 °C (104 °F) and 15% relative humidity, air may be cooled to nearly 21 °C (70 °F), with a dew point of 8 °C (46 °F).

Due to their optimal performance in dry conditions, evaporative coolers are widely utilised and most effective in arid, desert regions such as the southwestern USA and northern Mexico.

Comparison to air conditioning

Benefits

Cost-Effectiveness: Installation and operational expenses are significantly lower compared to central refrigerated air conditioning systems. Professional installation costs are estimated to be half or less, while operational expenses are approximately one-eighth of those of refrigerated air conditioning.

No Power Surges: Unlike refrigerated air conditioning units, evaporative coolers do not experience power spikes upon activation due to the absence of a compressor. Power consumption is confined to the fan and water pump, both of which have a relatively low current draw at startup.

Environmentally Friendly: Evaporative cooling systems utilise water as the working fluid, eliminating the need for special refrigerants like ammonia or CFCs. This reduces toxicity, replacement costs, and environmental impact, including ozone depletion concerns.

Ease of Installation and Maintenance: These systems can be installed by mechanically inclined individuals at a considerably lower cost than refrigeration equipment, which demands specialised skills and professional installation. Most basic evaporative coolers consist of only two mechanical parts: the fan motor and the water pump, both of which can be easily repaired or replaced by users, minimising service calls to HVAC contractors.

Enhanced Indoor Air Quality: The frequent and high volumetric flow rate of air through buildings significantly reduces the “age-of-air,” enhancing ventilation. Evaporative cooling also increases humidity, which can improve comfort and reduce static electricity issues, particularly in dry climates. Additionally, the cooling pad serves as an effective air filter, removing various contaminants, including urban ozone, irrespective of weather conditions.

Improved health and wellbeing: Evaporative coolers also humidify dry air, preventing problems such as itchy skin, throats and eyes. If you are considering buying an evaporative cooler, you need to ensure it is the right size for your space. Should the cooler be too big for the area it’s working in, it could lose effectiveness and could possibly lead to a build up of condensation so

consideration needs so consideration needs to be given to moisture sensitive equipment whenever you’re thinking about using evaporative cooling.

Minimal maintenance and high performance: These coolers generally require only a modest amount of maintenance. At Broughton EAP, we can assist you if you require any information about maintaining your evaporative cooler. The Comcool52 evaporative cooling system can

produce the equivalent of 20kW of cooling from just 2A. It features multiple fan speeds to cater for varying requirements and can either be fed directly from your tap or the 90l tank that sits inside it. Environments that are particularly likely to benefit from the system include warehouses and outdoor spaces where it is not possible to depend on conventional or traditional air conditioning solutions. The product also comes with a tank purge system, locking castors, a water filter and a diaphragm pump

Drawbacks

Performance Limitations: Evaporative coolers generally cannot achieve the same degree of temperature reduction as refrigerated air conditioning systems.

Impact of High Dewpoint Conditions: High dewpoint (humidity) conditions diminish the cooling efficiency of evaporative coolers, impacting their effectiveness.

Lack of Dehumidification: Unlike traditional air conditioners, evaporative cooling systems do not remove moisture from the air. While this can be advantageous in very dry locations, it may lead to increased humidity levels in humid climates, affecting thermal comfort at higher temperatures.

Comfort Concerns

The air emitted by the evaporative cooler typically contains 80–90% relative humidity, potentially raising interior humidity levels to as high as 65%. Such elevated humidity levels can hinder the evaporation rate of moisture from the skin, nose, lungs, and eyes, leading to discomfort.

Moreover, high humidity in the air can expedite corrosion, especially in the presence of dust particles. This corrosion can significantly shorten the lifespan of electronics and other equipment, posing durability concerns.

Additionally, heightened humidity levels may result in water condensation, particularly in certain scenarios such as around electrical equipment, computers, paper, books, and old wood surfaces. This condensation can lead to operational issues and potential damage.

Furthermore, odours and other outdoor contaminants may infiltrate indoor spaces through the evaporative cooling system if adequate filtration measures are not in place, potentially compromising indoor air quality.

Water Usage

Evaporative coolers necessitate a continuous supply of water to function effectively. However, water with a high mineral content, commonly known as hard water, can leave mineral deposits on the cooling pads and interior components of the cooler. Depending on the type and concentration of minerals, the replacement and disposal of pads could present safety hazards. While bleed-off and refill systems can mitigate this issue to some extent, they do not entirely eliminate it. Installation of an inline water filter, akin to those used in refrigerator drinking water or ice makers, can significantly reduce mineral deposits.

Maintenance Requirements

Mechanical components susceptible to rust or corrosion require regular cleaning or replacement due to the high moisture environment and potential mineral buildup, especially in areas with hard water.

Moreover, evaporative media must be replaced periodically to sustain optimal cooling performance. While wood wool pads are cost-effective, they necessitate replacement every few months. In contrast, higher-efficiency rigid media comes at a higher initial cost but offers greater longevity, lasting several years in proportion to water hardness. In regions with very hard water, however, rigid media may only remain effective for around two years before mineral scale accumulation adversely affects performance.

During cold winters, evaporative coolers must be drained and winterized to safeguard the water line and cooler from freeze damage. Subsequently, they must be de-winterized before the onset of the cooling season to ensure proper functionality.

Why purchase evaporative coolers?

Businesses invest in evaporative coolers for many reasons. They can use them to make a substantial saving on running costs whilst reducing their carbon emissions and reducing or even eliminating their reliance on refrigerant gases. Evaporative coolers are also an ideal match for event’s, outdoor applications and manufacturing sites.

Why choose Broughton EAP?

At Broughton EAP, we are waiting to hear from you if you wish to find out about our evaporative cooler products, air conditioning solutions, cooling fans and ventilation equipment. We have been in the business for well over three decades and always go the extra mile to deliver the perfect solutions for your air conditioning needs. Our evaporative coolers are inexpensive to install and operate and only require minimal maintenance. More and more commercial and industrial clients are choosing us when they wish to invest in products for improving the quality of air and heightening comfort levels.

Get in touch

There are several ways to contact us if you wish to find out more about our pioneering evaporative coolers. To reach us today, complete the form on our website, call +44(0)1527830610 or send an e-mail to sales@broughtoneap.co.uk. We can help you identify and invest in the ideal solution for your portable HVAC needs.