Portable air conditioners use the vapour compression cycle to produce cold air. Here we detail how this process works.

At Broughton EAP we manufacture portable industrial air conditioning units, portable electric heaters such as fan and infra red heaters, refrigerant dehumidifiers (which also use the vapour compression cycle) and cooling and ventilation fans. For details on our full product range then please visit www.broughtoneap.co.uk or call our expert sales team on 01527 830610.

9.1 REFRIGERATION AND REFRIGERATION SYSTEMS

Refrigeration is defined as the process of extracting heat from a lower-temperature heat source, substance, or cooling medium and transferring it to a higher-temperature heat sink. Refrigeration maintains the temperature of the heat source below that of its surroundings while transferring the extracted heat, and any required energy input, to a heat sink, atmospheric air, or surface water. A refrigeration system is a combination of components and equipment connected in a sequential order to produce the refrigeration effect. The refrigeration systems commonly used for air conditioning, including portable air conditioning units, can be classified by the type of input energy and the refrigeration process as follows:

- Vapor compression systems. In vapour compression systems, compressors activate the refrigerant by compressing it to a higher pressure and higher temperature level after it has produced its refrigeration effect. The compressed refrigerant transfers its heat to the sink and is condensed to liquid form. This liquid refrigerant is then throttled to a low-pressure, lowtemperature vapour to produce refrigerating effect during evaporation. Vapour compression systems are the most widely adopted refrigeration systems in both comfort, such as portable air conditioning units, and process air conditioning.

- Absorption systems. In an absorption system, the refrigeration effect is produced by thermal energy input. After absorbing heat from the cooling medium during evaporation, the vapour refrigerant is absorbed by an absorbent medium. This solution is then heated by direct-fired furnace, waste heat, hot water, or steam. The refrigerant is again vaporized and then condensed to liquid to begin the refrigeration cycle again.

- Air or gas expansion systems. In an air or gas expansion system, air or gas is compressed to a high pressure by mechanical energy. It is then cooled and expanded to a low pressure. Because the temperature of air or gas drops during expansion, a refrigeration effect is produced.

Refrigerants, Cooling Media, and Liquid Absorbents

Refrigerants. A refrigerant is the primary working fluid used for absorbing and transmitting heat in a refrigeration system. Refrigerants absorb heat at a low temperature and low pressure and release heat at a higher temperature and pressure. Most refrigerants undergo phase changes during heat absorption—evaporation—and heat releasing—condensation.

Cooling Media. A cooling medium is the working fluid cooled by the refrigerant to transport the cooling effect between a central plant and remote cooling units and terminals. In a large, centralized system, it is often more economical to use a coolant medium that can be pumped to remote locations where cooling is required. Chilled water, brine, and glycol are used as cooling media in many refrigeration systems. The cooling medium is often called a secondary refrigerant, because it obviates extensive circulation of the primary refrigerant.

Liquid Absorbents. A solution known as liquid absorbent is often used to absorb the vaporized refrigerant (water vapor) after its evaporation in an absorption refrigeration system. This solution, containing the absorbed vapor, is then heated at high pressure. The refrigerant vaporizes, and the solution is restored to its original concentration for reuse. Lithium bromide and ammonia, both in a water solution, are the liquid absorbents used most often in absorption refrigerating systems.

Azeotropic, Near Azeotropic, and Zeotropic

A refrigerant can either be a single chemical compound or a mixture (blend) of multiple compounds.

Azeotropic. These are blends of multiple components of volatilities (refrigerants) that evaporate and condense as a single substance and do not change their volumetric composition or saturation temperature when they evaporate or condense at a constant pressure. Components in a mixture of azeotropes cannot be separated from their constituents by distillation. Properties of azeotropic refrigerants are entirely different from those of their components and may be conveniently treated as a single chemical compound.

Near Azeotropic. Near-azeotropic refrigerants are blends whose characteristics are near to azeotropic. Although properties of near-azeotropic refrigerants are nearer to azeotropic than to nonazeotropic (zeotropic), near-azeotropic refrigerants are defined as zeotropic or nonazeotropic.

Zeotropic. These are blends of multiple components of volatilities (refrigerants) that evaporate and condense as a single substance and do change volumetric composition or saturation temperature when they evaporate or condense at a constant pressure.

Blends. Mixtures of refrigerants of two or more chemical compounds are blends. The advantage of a blend of multiple chemical compounds compared to a single compound is that the required properties of the blend can possibly be achieved by varying the fractional composition of the components.

Glide. Zeotropic mixtures, including near-azeotropic blends, show changes in composition because of the leaks, the difference between liquid and vapour phases, or the difference between the charge and circulation, or their combined effect. The shift in composition causes the change in evaporating and condensing temperature and pressure. The difference in dew point and bubble point in the temperature-concentration diagram of a zeotropic refrigerant during evaporation and condensation is called glide, expressed in °F (°C). A near-azeotropic refrigerant has a smaller glide than a zeotropic one. The midpoint between the dew point and bubble point is usually taken as the evaporating or condensing temperature for a nonazeotropic and near-azeotropic refrigerant. Hwang et al. (1997) showed that temperature drops during condensation and temperature increases during evaporation. Ideal or perfect azeotropic refrigerants are uncommon, whereas near-azeotropic ones are fairly common.

Numbering of Refrigerants

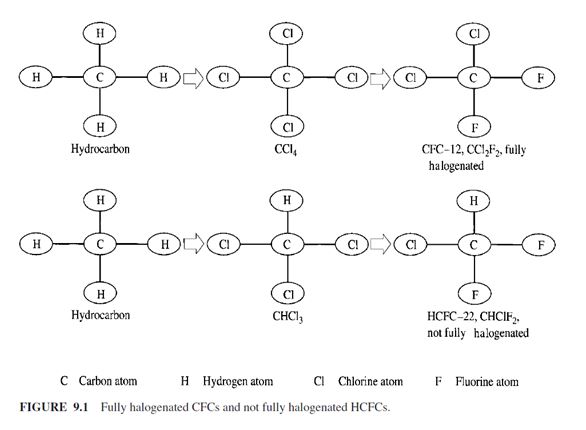

Before the invention of chlorofluorocarbons (CFCs), refrigerants were called by their chemical names. Because of the complexity of these names, especially the CFCs, the fully halogenated CFCs, and hydrochlorofluorocarbons (HCFCs), the not fully halogenated HCFCs (see Fig. 9.1), a numbering system was developed for hydrocarbons and halocarbons, and is used widely in the refrigeration industry. According to ANSI/ASHRAE Standard 34-1997, the first digit from the right is the number of fluorine atoms in the compound. The second digit from the right is one more than the number of hydrogen atoms in the compound. The third digit from the right is one less than the number of the carbon atoms in the compound. If the digit is zero, it is omitted from the number. The fourth digit from the right is the number of unsaturated carbon-carbon bonds in the compound. If the digit is zero it is also omitted from the number. For example, the chemical formula of HCFC-123 is CHCl2CF3:

There are 3 fluorine atoms, first digit from the right is 3

There is 1 hydrogen atom, second digit from the right is 1 + 1 – 2

There are 2 carbon atoms, third digit from the right is 2 – 1 – 1

No unsaturated C9C bonds, the fourth digit from the right is 0

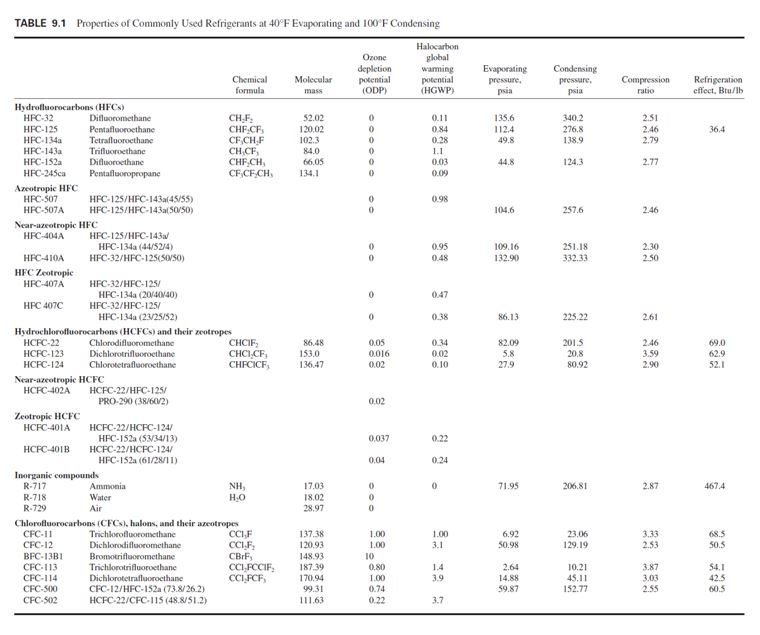

9.3 PROPERTIES AND CHARACTERISTICS OF REFRIGERANTS

Today, the preservation of the ozone layer is the first priority of refrigerant selection. In addition,

the global warming effect and the following factors should be considered.

Safety Requirements

Refrigerant may leak from pipe joints, seals, or component parts during installation, operation, or

accident. Therefore, refrigerants must be acceptably safe for humans and manufacturing processes,

with little or no toxicity or flammability.

In ANSI/ASHRAE Standard 34-1997, the toxicity of refrigerants is classified as class A or B.

Class A refrigerants are of lower toxicity. A class A refrigerant is one whose toxicity has not been

identified when its concentration is less than or equal to 400 ppm, based on threshold limit

value–time-weighted average (TLV-TWA) or equivalent indices. The TLV-TWA concentration is a

concentration to which workers can be exposed over an 8-h workday and a 40-h workweek without

suffering adverse effect. Concentration ppm means parts per million by mass.

Class B refrigerants are of high toxicity. A class B refrigerant produces evidence of toxicity

when workers are exposed to a concentration below 400 ppm based on a TLV-TWA concentration.

Flammable refrigerants explode when ignited. If a flammable refrigerant is leaked in the area of a

fire, the result is an immediate explosion. Soldering and welding for installation or repair cannot be

performed near such gases.

ANSI/ASHRAE Standard 34-1997 classifies the flammability of refrigerants into classes 1, 2,

and 3. Class 1 refrigerants show no flame propagation when tested in air at a pressure of 14.7 psia

(101 kPa) at 65°F (18.3°C). Class 2 refrigerants have a lower flammability limit (LFL) of more than

0.00625 lb/ ft3 (0.1 kg/m3) at 70°F (21.1°C) and 14.7 psia (101 kPa abs.), and a heat of combustion

less than 8174 Btu/lb (19,000 kJ/kg). Class 3 refrigerants are highly flammable, with an LFL less

than or equal to 0.00625 lb/ ft3 (0.1 kg/m3) at 70°F (21.1°C) and 14.7 psia (101 kPa abs.) or a heat

of combustion greater than or equal to 8174 Btu /lb (19,000 kJ/ kg).

A refrigerant’s safety classification is its combination of toxicity and flammability. According to

ANSI/ASHRAE Standard 34-1997, safety groups are classified as follows:

A1 lower toxicity and no flame propagation

- _ A2 lower toxicity and lower flammability

- _ A3 lower toxicity and higher flammability

- _ B1 higher toxicity and no flame propagation

- _ B2 higher toxicity and lower flammability

- _ B3 higher toxicity and higher flammability

For zeotropic blends whose flammability and toxicity may change as their composition changes, a

dual safety classification should be determined. The first classification denotes the classification of

the formulated composition of the blend. The second classification lists the classification of the

blend composition at the worst case of fractionation.

Effectiveness of Refrigeration Cycle

The effectiveness of refrigeration cycles, or coefficient of performance (COP), is one parameter that

affects the efficiency and energy consumption of the refrigeration system. It will be clearly defined

in a later section. The COP of a refrigeration cycle using a specific refrigerant depends mainly upon

the isentropic work input to the compressor at a given condensing and evaporating pressure differential,

as well as the refrigeration effect produced.

Evaporating and Condensing Pressures

It is best to use a refrigerant whose evaporating pressure is higher than that of the atmosphere so

that air and other noncondensable gases will not leak into the system and increase the condensing

pressure. The condensing pressure should be low because high condensing pressure necessitates

heavier construction of the compressor, piping, condenser, and other components. In addition, a

high-speed centrifugal compressor may be required to produce a high condensing pressure.

Oil Miscibility

When a small amount of oil is mixed with refrigerant, the mixture helps to lubricate the moving

parts of a compressor. Oil should be returned to the compressor from the condenser, evaporator, accessories,

and piping, in order to provide continuous lubrication. On the other hand, refrigerant can

dilute oil, weakening its lubricating effect; and when the oil adheres to the tubes in the evaporator

or condenser, it forms film that reduces the rate of heat transfer.

Inertness

An inert refrigerant does not react chemically with other materials, thus avoiding corrosion, erosion,

or damage to the components in the refrigerant circuit.

Thermal Conductivity

The thermal conductivity of a refrigerant is closely related to the efficiency of heat transfer in the

evaporator and condenser of a refrigeration system. Refrigerant always has a lower thermal conductivity

in its vapour state than in its liquid state. High thermal conductivity results in higher heat transfer

in heat exchangers.

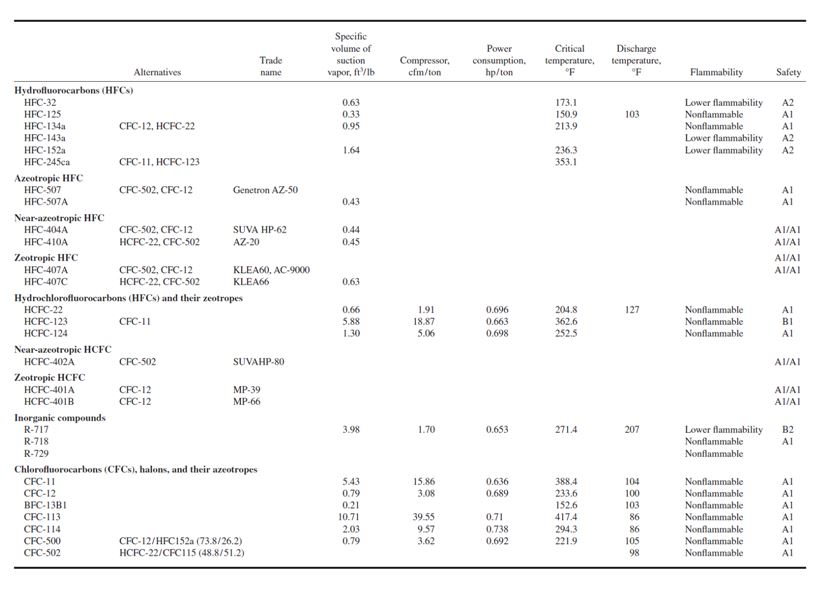

Refrigeration Capacity

The cubic feet per minute (cfm) suction vapor of refrigerant required to produce 1 ton of refrigeration

(liters per second to produce 1 kW of refrigeration) depends mainly on the latent heat of vaporization

of the refrigerant and the specific volume at the suction pressure. It directly affects the size

and compactness of the compressor and is one of the criteria for refrigerant selection.

Physical Properties

Discharge Temperature. A discharge temperature lower than 212°F (100°C) is preferable because

temperatures higher than 300°F (150°C) may carbonize lubricating oil or damage some of the

components.

Dielectric Properties. Dielectric properties are important for those refrigerants that will be in direct

contact with the windings of the motor (such as refrigerants used to cool the motor windings in

a hermetically sealed compressor and motor assembly).

Operating Characteristics

Leakage Detection. Refrigerant leakage should be easily detected. If it is not, gradual capacity reduction

and eventual failure to provide the required cooling will result. Most of the currently used

refrigerants are colourless and odourless.

9.4 PHASEOUT OF OZONE DEPLETION REFRIGERANTS

Refrigerant Use

The use of CFCs and HCFCs is a global concern. Approximately two-thirds of all fully halogenated

CFCs were used outside the United States in the mid-1980s. In 1985, the total use of halocarbons

in the United States was 611 million lb (0.28 million ton). These halocarbons were used in foam insulation,

automotive air conditioners, new systems of Air Conditioning and Refrigeration Institute

(ARI) members, and other products. Foam insulation blown by CFCs was the largest user. Automotive

air conditioners made up 19 percent of the total and CFCs purchased by ARI members for new

systems made up 5 percent of the total use. Of the CFCs and HCFCs purchased by ARI members,

HCFC-22 made up 77 percent, while CFC-11 and CFC-12 each made up about 10 percent.

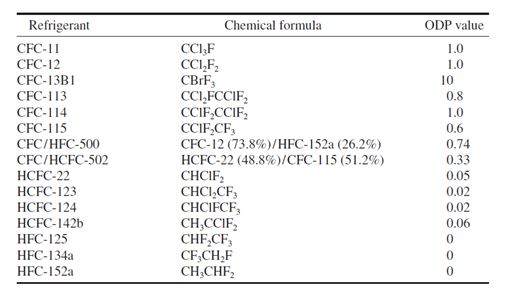

Ozone Depletion and Global Warming Potentials

To compare the relative ozone depletion caused by various refrigerants, an index called the ozone

depletion potential (ODP) has been proposed. ODP is the ratio of the rate of ozone depletion of 1 lb

of any halocarbon to that of 1 pound of CFC-11. The ODP of CFC-11 is assigned a value of 1. The

following are the ODP values for various refrigerants:

Similar to the ODP, the halocarbon global warming potential (HGWP) is the ratio of calculated

warming for each unit mass of gas emitted to the calculated warming for a unit mass of reference

gas CFC-11. The HGWPs of various refrigerants are listed in Table 9.1. In addition to the HGWP,

another global warming index uses CO2 as a reference gas. For example, 1 lb of HCFC-22 has the same effect on global warming as 4100 lb (1860 kg) of CO2 in the first 20 years after it is released

into the atmosphere. Its impact drops to 1500 lb (680 kg) at 100 years.

Phaseout of CFCs, Halons, and HCFCs

The theory of depletion of the ozone layer was proposed in 1974 by Rowland and Molina. (The

1995 Nobel Prize was awarded to F. Sherwood Rowland, Mario Molina, and Paul Crutzen for their

work in atmospheric chemistry and theory of ozone depletion.) Network station in Halley Bay,

Antarctica, established a baseline trend of ozone levels that helped scientists to discover the ozone

hole in 1985. National Aeronautics and Space Administration (NASA) flights into the stratosphere

over the arctic and antarctic circles found CFC residue where the ozone layer was damaged. Approximately

the same ozone depletion over the antarctic circle was found in 1987, 1989, 1990, and

- By 1988, antarctic ozone levels were 30 percent below those of the mid-1970s. The most severe

ozone loss over the antarctic was observed in 1992. Ground monitoring at various locations

worldwide in the 1980s has showed a 5 to 10 percent increase in ultraviolet radiation. Although

there is controversy about the theory of ozone layer depletion among scientists, as discussed in

Rowland (1992), action must be taken immediately before it is too late.

Montreal Protocol and Clean Air Act

In 1978, the Environmental Protection Agency (EPA) and the Food and Drug Administration (FDA)

of the United States issued regulations to phase out the use of fully halogenated CFCs in nonessential

aerosol propellants, one of the major uses at that time. On September 16, 1987, the European

Economic Community and 24 nations, including the United States, signed the Montreal Protocol.

This document is an agreement to phase out the production of CFCs and halons by the year 2000.

The Montreal Protocol had been ratified by 157 parties.

The Clean Air Act Amendments, signed into law in the United States on November 15, 1990,

governed two important issues: the phaseout of CFCs and a ban (effective July 1, 1992) on the deliberate

venting of CFCs and HCFCs. Deliberate venting of CFCs and HCFCs must follow the regulations

and guidelines of the EPA. In February 1992, then-President Bush called for an accelerated

phaseout of the CFCs in the United States. Production of CFCs must cease from January 1, 1996,

with limited exceptions for service to certain existing equipment.

In late November 1992, representatives of 93 nations meeting in Copenhagen also agreed to the

complete cessation of CFC production beginning January 1, 1996, and of halons by January 1,

1994, except continued use from existing (reclaimed or recycled) stock in developed nations. In

addition, the 1992 Copenhagen amendments and later a 1995 Vienna meeting revision agreed to

restrict the production of HCFCs relative to a 1989 level beginning from 2004 in developed nations

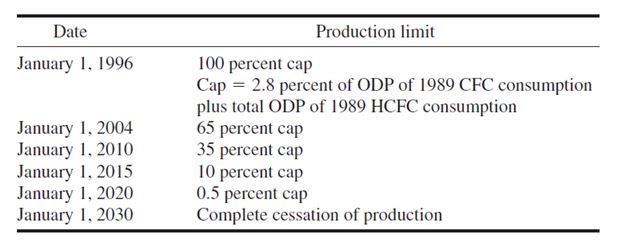

according to the following schedule:

Consumption indicates the production plus imports minus exports and feedstocks. The value of

2.8 percent cap is the revised value of the Vienna meeting in 1995 to replace the original value of 3.1 percent in the Copenhagen amendments. The Copenhagen amendments had been ratified by 58 parties.

Action and Measures

The impact of CFCs on the ozone layer poses a serious threat to human survival. The following

measures are essential:

Conversions and Replacements. Use alternative refrigerants (substitutes) to replace the CFCs in

existing chillers and direct-expansion (DX) systems. During the conversion of the CFC to

non–ozone depletion alternative refrigerants, careful analysis should be conducted of capacity, efficiency,

oil miscibility, and compatibility with existing materials after conversion. For many refrigeration

systems that already have a service life of more than 15 years, it may be cost-effective to

buy a new one using non-CFC refrigerant to replace the existing refrigeration package.

- HFC-134a and HCFC-22 are alternative refrigerants to replace CFC-12.

- HCFC-123, and HFC-245ca are alternative refrigerants to replace CFC-11 in large chillers. It is important to realize that HCFC-123 and HCFC-22 themselves are interim refrigerants and will be restricted in consumption beginning in 2004. HCFC-123 has a very low global warming potential and is widely used in centrifugal chillers. HCFC-22 is widely used in small and medium-size DX systems.

- HFC-134a, HFC-407C, and HFC-410A are alternative refrigerants to replace HCFC-22. HFC-407C is a near-azeotropic refrigerant of HFC-32/HFC-125/HFC-134a (23/25/52) [means (23%/25%/525)], and HFC-410A also a near-azeotropic refrigerant of HFC-32/HFC-125 (50/50).

- HFC-245ca or another new HFC possibly developed before 2004 will be the hopeful alternative to replace HCFC-123. In supermarkets, CFC-502 is a blend of HCFC-22/CFC-115 (48.8/ 51.2).

- HFC-404A, HFC-507, and HFC-410A are alternative refrigerants to replace CFC-502. HFC-404A is a near-azeotropic refrigerant of HFC-125/HFC-143a/HFC-134a(44/52/4); and HFC-507 is an azeotropic refrigerant of HFC-125/HFC-143a (45/ 55).

Reducing Leakage and Preventing Deliberate Venting. To reduce the leakage of refrigerant from

joints and rupture of the refrigeration system, one must detect the possible leakage, tighten the

chillers, improve the quality of sealing material, and implement preventive maintenance.

Prevent the deliberate venting of CFCs and HCFCs and other refrigerants during manufacturing,

installation, operation, service, and disposal of the products using refrigerants.

Avoid CFC and HCFC emissions through recovery, recycle, and reclaiming. According to

ASHRAE Guideline 3-1990, recovery is the removal of refrigerant from a system and storage in an

external container. Recycle involves cleaning the refrigerant for reuse by means of an oil separator

and filter dryer. In reclamation, refrigerant is reprocessed for new product specifications.

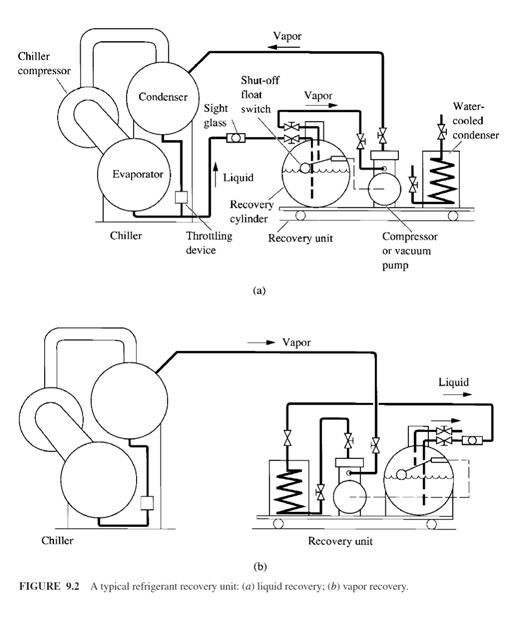

To avoid the venting of CFCs and HCFCs and other refrigerants, an important step is to use an

ARI-certified, portable refrigerant recovering/ recycling unit to recover all the liquid and remaining

vapor from a chiller or other refrigeration system. An outside recovery/ reclaiming service firm may

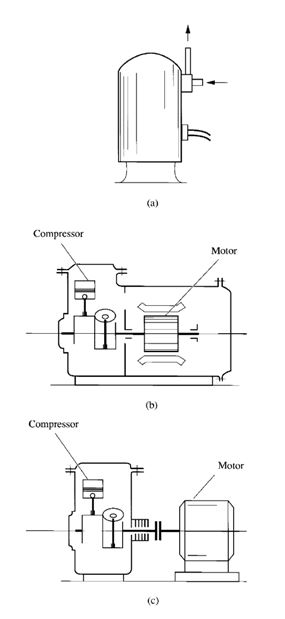

also be employed. A typical refrigerant recovery unit is shown in Fig. 9.2. It includes a recovery

cylinder, a vacuum pump or compressor, a water-cooled condenser, a sight glass, a shutoff float

switch, necessary accessories, pipes, and hoses.

To recover refrigerant from a chiller that has been shut down involves two phases: liquid recovery

and vapor recovery. Liquid recovery is shown in Fig. 9.2a. The vacuum pump or compressor

in the recovery unit creates a low pressure in the recovery cylinder. Liquid refrigerant is then

extracted from the bottom of the chiller into the recovery cylinder. If the recovery cylinder is not

large enough, the shutoff float switch ceases to operate the vacuum pump or compressor when the recovery cylinder is 80 percent full. Another empty recovery cylinder is used to replace the filled

cylinder. If the vapour enters the sight glass, which means that the liquid refrigerant is all extracted,

then the vacuum pump or compressor is stopped and the vapour recovery phase begins.

Vapour recovery is shown in Fig. 9.2b. The vacuum pump or compressor extracts the refrigerant

vapour from the top of the chiller. Extracted refrigerant vapour is then condensed to liquid form that

flows through the water-cooled condenser and is stored in the recovery cylinder. Noncondensable

gases are purged into the atmosphere from the recovery unit. Water at a temperature between 40

and 85°F (4.4 and 29.4°C) is often used as the condensing cooling medium. The recovered refrigerant

can be recycled or reclaimed as required.

In addition to the recovery of refrigerants from the chiller or other refrigeration system, refrigerant

vapour detectors should be installed at locations where refrigerant from a leak is likely to

concentrate. These detectors can set off an alarm to notify the operator to seal the leak.

Because of the worldwide effort to phase out CFCs, the latest result of a study conducted by the

National Oceanic and Atmospheric Administration (NOAA) and published in the journal Science

was reported by UPI science writer Susan Milius “. . . scientists are cheering a 1 percent reduction

during 1995 in the chemicals that slowly carry chlorine and bromine aloft to the stratosphere.”

(Air Conditioning, including portable air conditioning units, Heating and Refrigeration News, June 10, 1996, p. 2).

Status of CFC Replacements

Dooley (1997) showed that according to the ARI survey, in the United States there were about

80,000 CFC large-tonnage chillers in 1992, and most used CFC-11 as refrigerant. At the beginning

of 1997, some 18,981 chillers, or 24 percent of the total 80,000, had been phased-out CFC refrigerants.

Of these, 4813 chillers were converted to non-CFC refrigerant, and 14,168 chillers were

replaced by new chillers which used non-CFC refrigerant. The ratio of new replacements to conversions

was about 3 to 1. It is often cost-effective to replace an old chiller instead of to convert the

CFC refrigerant to alternatives in an existing chiller.

The ARI estimates that 53 percent of the 80,000 chillers in 1992 will remain in service on

January 1, 2000. This shows that the actual phaseout process was slower than expected.

For CFC-12, automotive cooling and supermarkets account for more than 90 percent of their servicing

requirements. Due to the vibrations and unsteady operating conditions, automotive cooling

required greater servicing losses and a faster phaseout schedule than large-tonnage chillers. The annual

amount of CFCs required to compensate for servicing losses came from stockpiles of virgin

CFCs and reclaimed CFCs. Because of the slower phaseout of CFC chillers, servicing demands

were greater than could be supplied from the reclaimed CFCs. The using up of the stockpiles of

virgin CFCs and thus a shortage of CFC supply may occur at the beginning of the twenty-first century

in the United States. The slower phaseout of CFCs indicated that there is a possibility of a

considerably longer period of servicing of HCFC equipment than called for in the production

phaseout schedule in the twenty-first century.

9.5 CLASSIFICATION OF REFRIGERANTS

Before the introduction of chlorofluorocarbons in the 1930s, the most commonly used refrigerants

were air, ammonia, sulphur dioxide, carbon dioxide, and methyl chloride. Until 1986, nontoxic

and nonflammable halogenated hydrocarbons with various ozone depletion potentials were used

almost exclusively in vapour compression refrigeration systems for air conditioning, such as portable air conditioning units. The impact of

ozone depletion of CFCs, halons, and HCFCs since the 1980s caused a worldwide decision to

phase out these refrigerants. A new classification of refrigerants into six groups based mainly on

ozone depletion will be helpful for the selection of non–ozone depletion refrigerants as well as

replacement of CFCs by alternative refrigerants (Table 9.1).

Hydrofluorocarbons

HFCs contain only hydrogen, fluorine, and carbon atoms. They contain no chlorine atoms, therefore

are environmentally safe, and cause no ozone depletion. They are designated by the prefix HFC.

HFC-134a is an attractive, long-term alternative to replace CFC-12 in reciprocating, scroll,

screw, and centrifugal compressors; and a long-term alternative for HCFC-22. It has a low 0.28

HGWP. HFC-134a is nonflammable, has an extremely low toxicity, and is classified as AI in

ANSI/ASHRAE Standard 34-1997 safety rating.

HFC-134a has a molecular mass of 102.3 instead of CFC-12’s molecular mass of 120.93. At a

condensing temperature of 100°F (37.8°C), HFC-134a’s condensing pressure is 138.83 psia (957

kPa abs.), whereas CFC-12’s is 131.65 psia (908 kPa abs.). A larger impeller of higher speed is needed for a centrifugal chiller to provide the same cooling capacity. Parsnow (1993) reported a

capacity loss of direct conversion from CFC-12 to HFC-134a of 8 to 10 percent, and an efficiency

loss of 1 to 2 percent. In Lowe and Ares (1995), in the conversion from CFC-12 to HFC-134a in the

Sears Tower centrifugal chillers, the compressor’s speed increased about 8.5 percent, there was a

cooling capacity loss of 12 to 24 percent, and efficiency was 12 to 16 percent worse.

HFC-134a has a poor mutual solubility with mineral oil because of a higher interfacial tension

between them. Polyolester-based synthetic lubricants should be used. Polyolester-based synthetic

oils are hygroscopic, so monitoring of the moisture content of the refrigerant is important. Halocarbons,

including HFC-134a, are compatible with containment materials. Concerning nonmetallic or

elastomer (such as gaskets) compatibility, Corr et al. (1993) reported that HFC-134a, an ester-based

synthetic oil mixture, has a smaller volume change of elastomer than CFC-12 and mineral oil.

HFC-134a may become one of the most widely used single-chemical-compound refrigerants during

the first half of the twenty-first century.

HFC-245ca also does not contain chlorine and bromine atoms, and its ODP is 0. Compared to

CFC-11, its efficiency will be 3 to 4 percent lower. Synthetic polyolester lubricant oil will be used.

Except for neoprene at high moisture content, common materials used in the refrigeration system

were shown to be compatible with HFC-245ca in tests. Smith et al. (1993) reported that mixtures of

HFC-245ca in air with a relative humidity of 43 percent and a HFC-245ca concentration range of

7 to 14.4 percent were observed to be flammable in tests.

Because of the higher isentropic work required by HFC-245ca compared to CFC-11 and HCFC-

123, for direct-drive centrifugal chillers, a large impeller is required during the conversion from

CFC-11 to HFC-245ca or from HCFC-123 to HFC-245ca.

HFC-245ca is a possible long-term alternative to CFC-11 and HCFC-123 in large centrifugal

chillers in the future. In the HFC group, HFC-32, HFC-125, HFC-143a, and HFC-152a all are seldom

used as a refrigerant of single compound only.

Azeotropic HFC

HFC-507 is an azeotrope of refrigerant blends of HFC-125/HFC-143a (45/55) of zero ozone

depletion and an HGWP of 0.96. It is a long-term alternative refrigerant to replace CFC-502 and

CFC-12 in low-temperature refrigeration systems whose evaporating temperatures are below 10°F

( 12.2°C). HFC-507 needs synthetic lubricant oil. According to ANSI/ASHRAE Standard 34-

1997, HFC-507 is allowed alternative designations for HFC-507A, a refrigeration blend of HFC-

125/HFC-143a (50/ 50).

The Linton et al. (1995) test results showed that compared to CFC-502, the cooling capacity of

HFC-507 was between 0.95 and 1.05. HFC-507 had an energy efficiency of 0.87 to 0.97 compared

to CFC-502.

Near-Azeotropic HFC

Near-azeotropic HFC is a refrigerant blend of zero ozone depletion and having rather small changes

in volumetric composition or saturation temperature, a small glide, when it evaporates or condenses

at a constant pressure. Near-azeotropic HFC-404A and HFC-410A require synthetic lubricant oil

instead of mineral oil and are nontoxic and nonflammable with a safety classification of A1/A1.

HFC-404A is a blend of HFC-125/HFC-143a/HFC-134a (44/52/4) of zero ozone depletion

and an HGWP of 0.94. It is a long-term alternative refrigerant for CFC-502 and CFC-12 both in

low-temperature refrigeration systems. HFC-404A has a temperature glide of 0.9°F (0.5°C) during

evaporation and a temperature glide of 0.6°F (0.33°C) during condensation. Snelson et al. (1995)

compared HFC-404A with CFC-502 from their test results. HFC-404A had the same, slightly

higher, or lower evaporating capacity at various condensing and evaporating temperatures. The energy

efficiency ratio of 0.89 to 0.99 was found at different evaporating temperatures Tev. The lower

the Tev, the lower the energy efficiency ratio, because of the higher compressor pressure ratio.

HFC-410A is a blend of HFC-32/HFC-125 (50/50) of zero ozone depletion and an HGWP of

0.43. It is a long-term alternative refrigerant to replace HCFC-22 and CFC-502. HFC-410A has a

temperature glide of 0.2°F (0.11°C) during evaporation and condensation. Hickman (1994) showed

that the compressor displacement, cfm/ton (L/ s kW), for HFC-410A is about 50 percent smaller

than that for HCFC-22; and the discharge pressure for 130°F (54.4°C) condensing is about 490 psia

(3379 kPa abs.), which is much higher than that for HCFC-22. It is often necessary to change the

original reciprocating compressor to a scroll compressor. A higher energy efficiency was reported

by a refrigerant manufacturer.

Zeotropic HFC

Zeotropic (nonazeotropic) HFCs are refrigerant blends of zero ozone depletion that have greater

temperature glide during evaporation and condensation. Zeotropic HFC-407A and HFC-407C also

require synthetic lubrication oil, instead of mineral oil; and both are nontoxic and nonflammable

with a safety classification of A1/A1.

HFC-407A is a blend of HFC-32/HFC-125/HFC-134a (20/40/40) of zero ozone depletion

with an HGWP of 0.49. It is a long-term alternative refrigerant for CFC-502 and CFC-12 in lowtemperature

refrigeration systems. HFC-407A showed a reduction in heat transfer in the evaporator

of a low-temperature system during tests. The system performance of HFC-407A was the lowest

compared to HFC-404A and HFC-507.

HFC-407C is a blend of HFC-32/HFC-125/134a (23/25/52) of zero ozone depletion with an

HGWP of 0.38. It is a long-term alternative refrigerant to replace HCFC-22 and CFC-502. Bivens

et al. (1994) compared HFC-407C to HCFC-22 during tests. For cooling and heating, the capacity

ratio ranged from 0.93 to 1.06, and the energy ratio ranged from 0.94 to 0.97. In-tube heat-transfer

coefficients during evaporation and condensation were 85 to 95 percent of HCFC-22 values.

HCFCs and Their Zeotropes

HCFCs contain hydrogen, chlorine, fluorine, and carbon atoms and are not fully halogenated.

HCFCs have a much shorter atmospheric life than CFCs and cause far less ozone depletion (0.02 to

0.1 ODP). They are designated by the prefix HCFC. Their consumption is scheduled to be reduced

gradually starting from 2004 and will be completely phased out in 2030 in developed nations, except

for a limited amount for service, as discussed previously.

HCFC-22 has an ODP of 0.05 and an HGWP of 0.40. It is nonflammable with a safety classification

of A1. HCFC-22 is partially miscible with mineral oil. At 40°F (4.4°C), its evaporating pressure

is 82.09 psia (566 kPa abs.), and at 100°F (37.8°C) its condensing pressure is 201.5 psia (1389

kPa abs.), the highest of currently used HCFC and CFC refrigerants. HCFC-22 has a smaller compressor

displacement among the HCFCs and CFCs. All these factors make it an interim alternative

to replace CFC-12. HCFC-22 was the most widely used refrigerant in reciprocating and scroll compressors

in small and medium-size packaged units in the 1990s in the United States.

HCFC-123 is an interim alternative to replace CFC-11 in low-pressure centrifugal chillers. It has

an ODP of 0.02 and a very low HGWP of 0.02. HCFC-123 is nonflammable and of lower toxicity

with a safety classification of B1. In 1997, DuPont raised the allowable exposure limit (AEL) of

HCFC-123 to 50 ppm. Smithhart and Crawford (1993) reported that for chillers with direct conversion

from CFC-11 to HCFC-123, there was about a decrease of 0 to 5 percent in capacity and a 2 to

4 percent decrease in efficiency. A conversion of refrigerant from CFC-11 to HCFC-123 in an existing

chiller may require changing its lubricants, seals, and motor windings of hermetic compressors.

Because HCFC-123 has a low ODP, a very low HGWP, and a 15 percent higher energy efficiency

in centrifugal chillers than HFC-134a does, if no acceptable alternative can be found, the use

of HCFC-123 in centrifugal chillers may be considered longer than the cap specified in the Vienna

meeting in 1995, as listed in Sec. 9.4, in the twenty-first century.

HCFC-124 has an ODP of 0.02. It is nonflammable and has a safety classification of A1. HCFC-

124 is an interim alternative refrigerant to replace CFC-114.

Near-azeotropic HCFC-402A is a blend of HCFC-22/HFC-125/PRO-290 (38/60/2) with an

ODP of 0.02 and an HGWP of 0.63. Here PRO-290 represents propane, which is a more highly

flammable refrigerant with a safety classification of A3. HCFC-402A is nonflammable and has a

safety classification of A1/A1. It needs polyolester or alkyl-benzene-based lubricant oil. HCFC-

402A is an interim alternative refrigerant to replace CFC-502.

Zeotropic HCFC-401A is a blend of HCFC-22/HCFC-124/HFC-152a (53/34/13) with an ODP

of 0.037 and an HGWP of 0.22; and HCFC-401B is a blend of HCFC-22/HCFC-124/HFC-152a

(61/28/11) with an ODP of 0.04 and an HGWP of 0.24. Both HCFC-401A and HCFC-401B are

nonflammable and have a safety classification of A1/A1. They both need alkyl-benzene-based lubricant

oil. HCFC-401A is an interim alternative refrigerant to replace CFC-12, and HCFC-401B is an

interim alternative refrigerant to replace CFC-12 in low-temperature refrigeration systems.

Inorganic Compounds

These compounds include ammonia (NH3), water (H2O), and gases used in the gas expansion systems.

As refrigerants, they were used far earlier than the halocarbons. Air is a mixture of nitrogen,

oxygen, argon, rare gases, and water vapour. Air has zero ozone depletion and is a zeotropic blend that

has a temperature glide of 5.5°F (3°C) at atmospheric pressure. Ammonia also has zero ozone

depletion. It has a high operating pressure at 40°F (4.4°C) evaporating and 100°F (37.8°C) condensing.

Ammonia compressors show a smaller cfm/ton displacement and higher energy efficiency than

HCFC-22 compressors. Leakage of ammonia is easily detected due to its objectionable odour.

Ammonia attacks copper even in the presence of a small amount of moisture. It is of higher toxicity.

An ammonia-air mixture is flammable if the concentration of NH3 by volume is within 16 to

25 percent. The mixture may explode if the ignition source is above 1200°F (650°C). Because the

safety classification of ammonia is B2—lower flammability and higher toxicity—it is not allowed

to be used in comfort air conditioning such as portable air conditioning units in the United States.

Water has a zero ODP and is readily available. At 40°F (4.4°C) evaporating and 100°F (37.8°C)

condensing, water’s evaporating and condensing pressures are both below atmospheric. Air and

other noncondensable gases must be purged out of the refrigeration system periodically.

CFCs, Halons, and Their Zeotropes

CFCs including CFC-11, CFC-12, CFC-113, and CFC-114, have an ODP from 0.8 to 1.0. Halons

including BFC-13B1 have an ODP of 10. Their azeotropics CFC-500 and CFC-502 have ODPs of

0.74 and 0.22, respectively. Production of all these CFCs, halons, and their azeotropes ceased in developed

nations since January 1, 1996. However, a limited amount of these refrigerants, used to service

the refrigeration systems that have not been converted or replaced by non–ozone depletion refrigerants,

may be extended to the beginning of the twenty-first century.

9.6 REFRIGERATION PROCESSES AND REFRIGERATION CYCLES

Refrigeration Processes

A refrigeration process indicates the change of thermodynamic properties of the refrigerant and the

energy transfer between the refrigerant and the surroundings. The following refrigeration processes

occur during the operation of a vapour compression refrigerating system:

- In this process, the refrigerant evaporates at a lower temperature than that of its

surroundings, absorbing its latent heat of vaporization.

- Saturated refrigerant vapour is usually superheated to ensure that liquid refrigerant

does not flow into the compressor.

- Refrigerant is compressed to a higher pressure and temperature for condensation.

- Gaseous refrigerant is condensed to liquid form by being desuperheated, then condensed,

and finally subcooled, transferring its latent heat of condensation to a coolant.

- Throttling and expansion. The higher-pressure liquid refrigerant is throttled to the lower evaporating

pressure and is ready for evaporation.

The following refrigeration processes occur during the operation of an air or gas expansion

refrigeration system:

- Air or gas is compressed to a higher pressure and temperature.

- Heat release. Heat is released to the surroundings at constant pressure in order to reduce the temperature

of the air or gas.

- Throttling and expansion. Air or gas is throttled and expanded so that its temperature is lowered.

- Heat absorption. Heat is absorbed from the surroundings because of the lower air or gas temperature.

Refrigeration Cycles

Most refrigerants undergo a series of evaporation, compression, condensation, throttling, and expansion

processes, absorbing heat from a lower-temperature reservoir and releasing it to a highertemperature

reservoir in such a way that the final state is equal in all respects to the initial state. It is

said to have undergone a closed refrigeration cycle. When air or gas undergoes a series of compression,

heat release, throttling, expansion, and heat absorption processes, and its final state is not

equal to its initial state, it is said to have undergone an open refrigeration cycle.

Both vapor compression and air or gas expansion refrigeration cycles are discussed in this chapter.

Absorption refrigeration cycles are covered in Chap. 14.

Unit of Refrigeration

In inch-pound (I-P) units, refrigeration is expressed in British thermal units per hour, or simply Btu/h.

A British thermal unit is defined as the amount of heat energy required to raise the temperature of one

pound of water one degree Fahrenheit from 59°F to 60°F; and 1 Btu/h 0.293 watt (W).

Another unit of refrigeration widely used in the HVAC&R industry is ton of refrigeration, or

simply ton. As mentioned before, 1 ton 12,000 Btu/h of heat removed. This equals the heat

absorbed by 1 ton (2000 lb) of ice melting at a temperature of 32°F over 24 h.

Because the heat of fusion of ice at 32°F is 144 Btu / lb:

1 ton = (1 X 2000 X 144)/24 = 12,000 Btu/hr, also 1 ton = 3.516 kW.

9.7 GRAPHICAL AND ANALYTICAL EVALUATION OF REFRIGERATION

Pressure-Enthalpy Diagram

The pressure-enthalpy p-h diagram is the most common graphical tool for analysis and calculation

of the heat and work transfer and performance of a refrigeration cycle. A single-stage refrigeration

cycle consists of two regions: the high-pressure region, or high side, and the low-pressure region, or

low side. The change in pressure can be clearly illustrated on the p-h diagram. Also, both heat and

work transfer of various processes can be calculated as the change of enthalpy and are easily shown

on the p-h diagram.

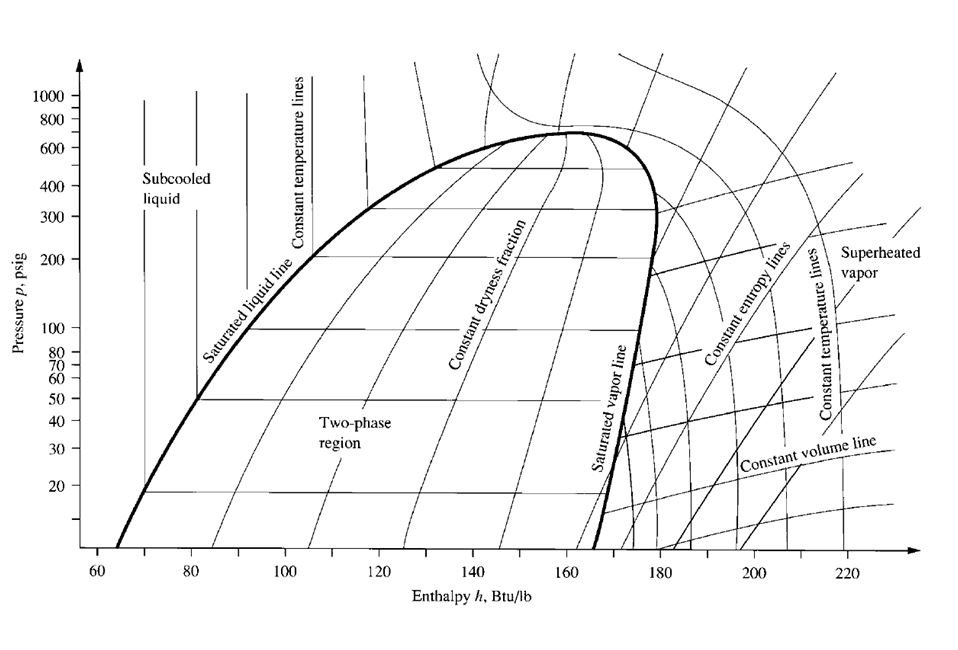

Figure 9.3 is a skeleton p-h diagram for refrigerant HCFC-22. Enthalpy h (in Btu/ lb) is the

abscissa, and absolute pressure (psia) or gauge pressure (psig), both expressed in logarithmic scale,

is the ordinate. The saturated liquid line separates the subcooled liquid from the two-phase region in

which vapour and liquid refrigerants coexist. The saturated vapour line separates this two-phase

region from the superheated vapour. In the two-phase region, the mixture of vapour and liquid is

subdivided by the constant-dryness-fraction quality line.

The constant-temperature lines are nearly vertical in the subcooled liquid region. At higher temperatures,

they are curves near the saturated liquid line. In the two-phase region, the constant-temperature

lines are horizontal. In the superheated region, the constant-temperature lines curve down

sharply. Because the constant-temperature lines and constant-pressure lines in the two-phase region

are horizontal, they are closely related. The specific pressure of a refrigerant in the two-phase

region determines its temperature, and vice versa.

Also in the superheated region, the constant-entropy lines incline sharply upward, and constantvolume

lines are flatter. Both are slightly curved.

FIGURE 9.3 Skeleton of pressure-enthalpy p-h diagram for HCFC-22.

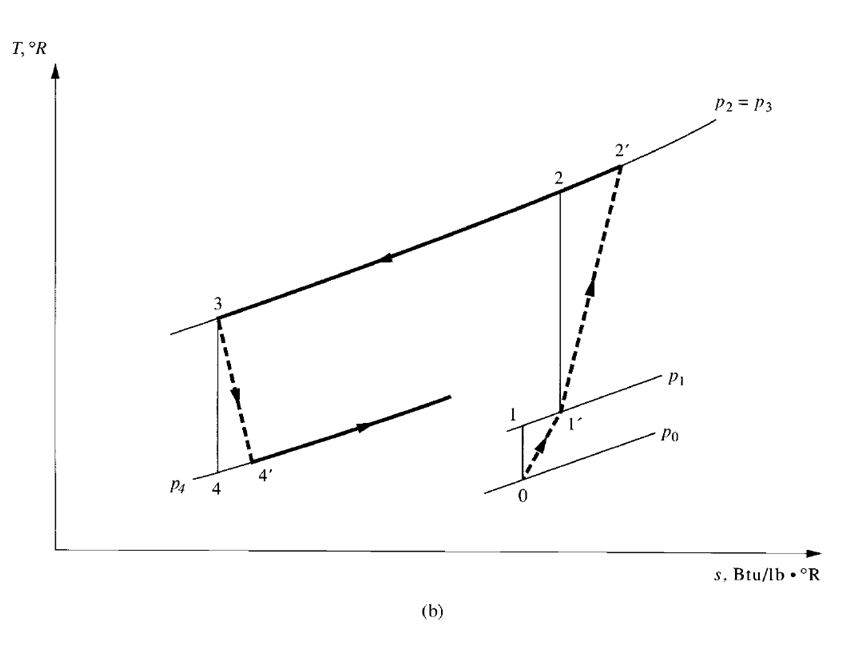

Temperature-Entropy Diagram

The temperature-entropy T-s diagram is often used to analyze the irreversibilities in a refrigeration

cycle, as well as in the system, in order to select optimum operating parameters and improve performance

of the system. In a temperature-entropy T-s diagram, entropy s, Btu / lb°R, is the abscissa of the diagram and temperature T, °R, is the ordinate. A T-s diagram is more suitable for evaluating

the effectiveness of an air expansion refrigeration cycle.

Analytical Evaluation of Cycle Performance

Swers et al. (1972) proposed a thermodynamic analysis of degradation of available energy and irreversibility

in a refrigerating system, and Tan and Yin (1986) recommended a method of exergy

analysis. The exergy of a working substance e, Btu / lb (kJ / kg), is defined as:

e = h – ha – TRa (s – sa) (9.1)

where h, ha = enthalpy of working substance and ambient state, Btu / lb (kJ /kg)

TRa = absolute temperature of ambient state, °R (K)

s, sa = entropy of working substance and ambient state, Btu / lb∙°R (kJ/kg∙K)

Both analyses are effective tools in the selection of optimum design and operating parameters by

means of complicated analysis. They require extensive supporting data and information.

For most analyses of refrigeration cycle performance and design and operation of refrigeration

systems in actual applications, satisfactory results can be obtained by using the steady flow energy

equation, heat and work transfer, and energy balance principle. If a more precise and elaborate

analysis is needed in research or for detailed improvements of refrigeration systems, the references

at the end of this chapter can be consulted.

9.8 CARNOT REFRIGERATION CYCLE

The Carnot refrigeration cycle is a reverse engine cycle. All processes in a Carnot refrigeration

cycle are reversible, so it is the most efficient refrigeration cycle.

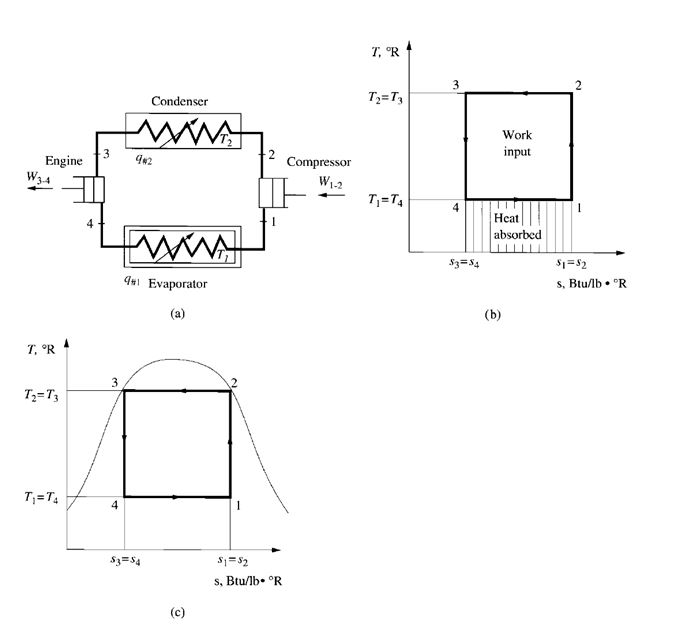

Figure 9.4a is a schematic diagram of a Carnot cycle refrigerating system, and Fig. 9.4b shows

the Carnot refrigeration cycle using gas as the working substance. This Carnot cycle is composed of

four reversible processes:

- An isothermal process 4-1 in which heat q#1 is extracted at constant temperature TR1 per lb (kg)

of working substance

- An isentropic compression process 1-2

- An isothermal process 2-3 in which q#2 is rejected at constant temperature TR2 per lb (kg) of

working substance

- An isentropic expansion process 3-4

Figure 9.4c shows the Carnot refrigeration cycle using vapour as the working substance. Wet vapour

is the only working substance where heat supply and heat rejection processes can occur easily

at constant temperature. This is because the temperatures of wet vapour remain constant when latent

heat is supplied or rejected.

As in the gas cycle, there are two isothermal processes 4-1 and 2-3 absorbing heat at temperature

TR1 and rejecting heat at TR2, respectively, and two isentropic processes, one for compression

1-2 and another for expansion 3-4.

Performance of Carnot Refrigeration Cycle

According to the first law of thermodynamics, often called the law of conservation of energy, when

a system undergoes a thermodynamic cycle, the net heat supplied to the system is equal to the net

FIGURE 9.4 Carnot refrigeration cycle: (a) schematic diagram; (b) gas cycle; (c) vapour cycle.

work done, or:

Heat supply + heat rejected = net work done (9.2)

Referring to Fig. 9.4a, in a Carnot refrigeration cycle,

q#1– q#2=- W

or,

q#1= q#2– W (9.3)

q#2= q#1+ W

where q#1 = heat supplied from surroundings per lb (kg) of working substance at temperature T1;

sign of q#1 is positive

q#2 = heat rejected to sink per lb (kg) of working substance at temperature T2; sign of q#2

is negative

W = net work done by system; sign is positive, or if it is a work input to system, sign is

Negative

The heat extracted from the source at temperature TR1 by the working substance, i.e., the refrigerating

effect per lb (kg) of working substance, is

q#1= TR1(s1– s4) (9.4)

where s1, s4= entropy at state points 1 and 4, respectively, Btu / lb°R (kJ/kgK). Heat rejected to

the heat sink at temperature TR2 can be calculated as

FIGURE 9.4 Carnot refrigeration cycle: (a) schematic diagram; (b) gas cycle; (c) vapour cycle.

work done, or:

Heat supply + heat rejected = net work done (9.2)

Referring to Fig. 9.4a, in a Carnot refrigeration cycle,

q#1– q#2=- W

or,

q#1= q#2– W (9.3)

q#2= q#1+ W

where q#1 = heat supplied from surroundings per lb (kg) of working substance at temperature T1;

sign of q#1 is positive

q#2 = heat rejected to sink per lb (kg) of working substance at temperature T2; sign of q#2

is negative

W = net work done by system; sign is positive, or if it is a work input to system, sign is

Negative

The heat extracted from the source at temperature TR1 by the working substance, i.e., the refrigerating

effect per lb (kg) of working substance, is

q#1= TR1(s1– s4) (9.4)

where s1, s4= entropy at state points 1 and 4, respectively, Btu / lb°R (kJ/kgK). Heat rejected to

the heat sink at temperature TR2 can be calculated as

the ratio of heat rejection to the work input, or

COPhp = q#2 / win (9.9)

For a heat recovery system, the useful effect is q#1 and q#2. In such a condition, COPhr is defined as

the ratio of the sum of the absolute values of refrigerating effect and heat rejection to the absolute

value of the work input, i.e.,

COPhr = │q#1│+ │q#2│/ Win (9.10)

9.10 SINGLE-STAGE IDEAL VAPOR COMPRESSION CYCLE

The Carnot cycle cannot be achieved for the vapour cycle in actual practice because liquid slugging

would occur during compression of the two-phase refrigerant. In addition, the mixture, mostly liquid,

does very little work when it expands after condensation in the heat engine. Therefore, a single-

stage ideal vapour compression cycle is used instead of the Carnot cycle.

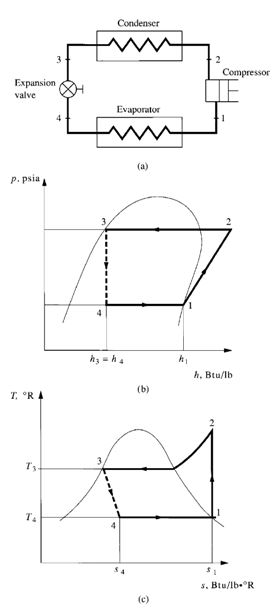

Figure 9.5 shows an ideal single-stage vapour compression cycle in which compression occurs in

the superheated region. A throttling device, such as an expansion valve, is used instead of the heat

engine. Single-stage means that there is only one stage of compression. An ideal cycle is one in

which the compression process is isentropic and the pressure losses in the pipeline, valves, and

other components are negligible. All the refrigeration cycles covered in this chapter are ideal cycles

except the air expansion refrigeration cycle.

Vapour compression means that the vapour refrigerant is compressed to a higher pressure, and then

the condensed liquid is throttled to a lower pressure to produce the refrigerating effect by evaporation.

It is different from the absorption or air expansion refrigeration cycle.

Flow Processes

Figure 9.5b and c shows the refrigeration cycle on p-h and T-s diagrams. The refrigerant evaporates

entirely in the evaporator and produces the refrigerating effect. It is then extracted by the compressor

at state point 1, compressor suction, and is compressed isentropically from state point 1 to 2. It

is next condensed to liquid in the condenser, and the latent heat of condensation is rejected to the

heat sink. The liquid refrigerant, at state point 3, flows through an expansion valve, which reduces it

to the evaporating pressure. In the ideal vapour compression cycle, the throttling process at the expansion

valve is the only irreversible process, usually indicated by a dotted line. Some of the liquid

flashes into vapour and enters the evaporator at state point 4. The remaining liquid portion evaporates

at the evaporating temperature, thus completing the cycle.

Cycle Performance

For the evaporating process between points 4 and 1, according to the steady flow energy equation,

(h4 + v24) / (2gc * 778) + q# = (h1 + v21) / (2gc * 778) + W (9.11)

whehre h1, h4= enthalpy of refrigerant at points 1 and 4, respectively, Btu / lb (J /kg)

v1, v4= velocity of refrigerant at points 1 and 4, respectively, ft / s (m/ s)

q# =heat supplied per lb (kg) of working substance during evaporation process, Btu/ lb

(J /kg)

gc= dimensional conversion factor, 32 lbm∙ft / lbf∙s2

Because no work is done during evaporation, the change of kinetic energy between points 4 and 1 is

small compared with other terms in Eq. (9.11), and it is usually ignored. Then

h4 + q# = h1 + 0

The refrigerating effect qrf, Btu / lb (J / kg), is qrf = q# = h1 – h4

FIGURE 9.5 Single-stage ideal vapour compression cycle: (a)

schematic diagram; (b) p-h diagram; (c) T-s diagram.

9.24 CHAPTER NINE

For isentropic compression between points 1 and 2, applying the steady flow energy equation and

ignoring the change of kinetic energy, we have

h1 + 0 = h2 + W

-W = h2 – h1

Work input to the compressor Win, Btu / lb (kJ / kg), is given as

Win = h2– h1 (9.13)

Similarly, for condensation between points 2 and 3,

h2+ q#= h3+ 0

The heat released by the refrigerant in the condenser- q#, Btu / lb (kJ / kg), is

-q#= h2– h3 (9.14)

For the throttling process between points 3 and 4, assuming that the heat loss is negligible

h3+ 0 = h4 + 0

or h3= h4 (9.15)

The COPref of the single-stage ideal vapour compression cycle is

COPref = Refrigeration Effect/Work Input = (h1 – h4) / (h2 – h1) (9.16)

The mass flow rate of refrigerant, lb/h (kg/ s), flowing through the evaporator is

mr = Qrc / qrf (9.17)

where Qrc refrigerating capacity, Btu /h (W). From Eq. (9.16), the smaller the difference between

the condensing and evaporating pressures, or between condensing and evaporating temperatures,

the lower the Win input to the compressor at a specific Qrc and, therefore, the higher the COP.

A higher evaporating pressure pev and evaporating temperature Tev or a lower condensing pressure

pcon and condensing temperature Tcon will always conserve energy

Determination of Enthalpy by Polynomials

During the performance analysis of a refrigeration cycle, the enthalpies h of the refrigerant at

various points must be determined in order to calculate the refrigeration effect, work input, and

COP. The enthalpy of refrigerant at saturated liquid and saturated vapour state is a function of

saturated temperature or pressure. In other words, saturated temperature Ts and saturated pressure

pss of the refrigerant are dependent upon each other. Therefore, it is more convenient to evaluate

the enthalpy of refrigerant in terms of saturated temperature Ts within a certain temperature

range

h = ƒ (Ts) (9.18)

REFRIGERANTS, REFRIGERATION CYCLES, AND REFRIGERATION SYSTEMS 9.25

The enthalpy differential along the constant-entropy line within a narrower temperature range can

be calculated as

h2– h1= F(Ts2– Ts1) (9.19)

where h1, h2= enthalpy of refrigerant on constant-entropy line at points 1 and 2, Btu/ lb (kJ /kg)

Ts1, Ts2= temperature of saturated refrigerant at points 1and 2,°F (°C)

From the refrigerant tables published by ASHRAE, the following polynomial can be used to calculate

the enthalpy of saturated liquid refrigerant hlr, Btu / lb (kJ / kg), from its temperature Ts1 at a saturated

temperature from 20 to 120°F (- 7 to 50°C) with acceptable accuracy:

hlr= a1 + a2Ts1+ a3T2s1+ a4T3s1 (9.20)

where a1, a2, a3, a4= coefficients. For HCFC-22,

a1= 10.409 a2= 0.26851 a3 = 0.00014794 a4= 5.3429 X 10-7

Similarly, the polynomial that determines the enthalpy of saturated vapour refrigerant hvr, Btu / lb

(kJ/ kg), from its temperature Tsv in the same temperature range is

hvr = b1 + b2Tsv + b3T2sv + b4T3sv (9.21)

whereb1, b2, b3, b4 _ coefficients. For HCFC-22,

b1 = 104.465 b2 = 0.098445 b3 =-0.0001226 b4 =-9.861 X 10-7

The polynomial that determines the enthalpy changes of refrigerant along the constant-entropy line

for an isentropic compression process between initial state 1 and final state 2 is

h2–h1c1 _ c2(Ts2 _ Ts1) _ c3(Ts2 _ Ts1)2 _ c4(Ts2 _ Ts1)3 (9.22)

where c1, c2, c3, c4= coefficients

Ts1, Ts2= saturated temperature of vapour refrigerant corresponding to its pressure at initial

state 1 and final state 2,°F (°C)

For HCFC-22 within a saturated temperature range of 20 to 100°F:

c1 =-0.18165 c2=+0.21502 c3=-0.0012405 c4=+8.198 X 10-6

Computer programs are available that calculate the coefficients based on ASHRAE’s refrigerant tables

and charts.

Refrigeration Effect, Refrigerating Load, and Refrigerating Capacity

The refrigeration effect qrf, Btu / lb (J /kg or kJ/ kg), is the heat extracted by a unit mass of refrigerant

during the evaporating process in the evaporator. It can be calculated as

qrf=hlv –hen (9.23)

where hen, hlv= enthalpy of refrigerant entering and leaving evaporator, Btu / lb (J / kg). Refrigerating

load Qrl, Btu /h (W), is the required rate of heat extraction by the refrigerant in the evaporator. Itcan be calculated as

Qrl=m˙r(hlv–hen) (9.24)

wherem˙r= mass flow rate of refrigerant flowing through evaporator, lb/h (kg/ s).

Refrigerating capacity, or cooling capacity, Qrc, Btu /h (W), is the actual rate of heat extracted by

the refrigerant in the evaporator. In practice, the refrigeration capacity of the equipment selected is

often slightly higher than the refrigerating load. This is because the manufacturer’s specifications

are a series of fixed capacities. Occasionally, equipment can be selected so that its capacity is just

equal to the refrigeration load required. Refrigeration capacity Qrccan be calculated as

Qrc =m˙r(hrlv –hren) (9.25)

where hren, hrlv= enthalpy of refrigerant actually entering and leaving evaporator, Btu / lb (J /kg)

9.11 SUBCOOLING AND SUPERHEATING

Subcooling

Condensed liquid refrigerant is usually subcooled to a temperature lower than the saturated temperature

corresponding to the condensing pressure of the refrigerant, shown in Fig. 9.6a as point 3’.

This is done to increase the refrigerating effect. The degree of subcooling depends mainly on the

temperature of the coolant (e.g., atmospheric air, surface water, or well water) during condensation,

and the construction and capacity of the condenser.

The enthalpy of subcooled liquid refrigerant hsc, Btu / lb (J / kg), can be calculated as

hsc= hs,con –cpr(Ts,con –Tsc) (9.26)

where hs,con= enthalpy of saturated liquid refrigerant at condensing temperature, Btu/ lb (J /kg)

cpr= specific heat of liquid refrigerant at constant pressure, Btu/ lb ∙°F (J /kg∙°C)

Ts,con= saturated temperature of liquid refrigerant at condensing pressure,°F (°C)

Tsc= temperature of subcooled liquid refrigerant,°F (°C)

Enthalpy hscis also approximately equal to the enthalpy of the saturated liquid refrigerant at subcooled

temperature.

Superheating

As mentioned before, the purpose of superheating is to avoid compressor slugging damage. Superheating

is shown in Fig. 9.6b. The degree of superheat depends mainly on the type of refrigerant

feed and compressor as well as the construction of the evaporator. These are covered in detail in

Chap. 11.

Example 9.1. A 500-ton (1760-kW) single-stage centrifugal vapor compression system uses

HCFC-22 as refrigerant. The vapour refrigerant enters the compressor at dry saturated state. The

compression process is assumed to be isentropic. Hot gas is discharged to the condenser and

condensed at a temperature of 95°F (35°C). The saturated liquid refrigerant then flows through a

throttling device and evaporates at a temperature of 35°F (1.7°C). Calculate:

- The refrigeration effect

- The work input to the compressor

FIGURE 9.6 (a) Subcooling and (b) superheating.

- The coefficient of performance of this refrigeration cycle

- The mass flow rate of the refrigerant

Recalculate the COP and the energy saved in work input if the refrigerant is subcooled to a temperature

of 90°F (32.2°C).

Solution

- From Eq. (9.20), the enthalpy of the saturated liquid refrigerant at a temperature of 95°F (35°C),

point 3 as shown in Fig. 9.5a, is

h3=h4= 10.409 + 0.26851Ts+ 0.0001479T s2 + 5.3429 X 10-7T s3

= 10.409 + 0.26851(95) + 0.0001479(95)2+ 5.3429 X 10-7(95)3

= 10.409 + 25.508 + 1.335 + 0.458 = 37.71 Btu / lb

From Eq. (9.21), the enthalpy of saturated vapour refrigerant at a temperature of 35°F (1.7°C),

point 1, is

h1 = 104.465 + 0.098445Ts – 0.0001226T s2– 9.861 X 10-7T s3

= 104.47 + 0.098445(35) – 0.0001226(35)2– 9.861 X 10-7(35)3

= 104.47 + 3.445 – 0.150 – 0.042 = 107.72 Btu / lb

Then the refrigeration effect is calculated as

qrf=h1–h4= 107.72 – 37.71 = 70.01 Btu/ lb (162.8 kJ /kg)

- From Eq. (9.22), the enthalpy differential h2 _ h1 on the constant-entropy line corresponding to

a saturated temperature differential Ts2–Ts1 = 95 – 35 = 60°F in the two-phase region is

h2–h1=-0.18165 + 0.21502(Ts2–Ts1) – 0.0012405(Ts2–Ts1)2+ 8.1982 X 10-6(Ts2 _ Ts1)3

=- 0.18165 + 0.21502(60) – 0.0012405(60)2+ 8.1982 X 10-6(60)3

=-0.182 + 12.901 – 4.466 +1.771 = 10.02 Btu / lb

That is, the work input Win= h2–h1 = 10.024 Btu/ lb (23.73 kJ / kg).

- According to Eq. (9.16), COPref of the refrigerating system is calculated as

COPref = qrf/Win = 70.01/10.024 = 6.98

- From Eq. (9.17), the mass flow rate of the refrigerant can be calculated as

m˙ r= Qrc/ qrf = 500 X 12,000 / 70.01 = 85,702 lb / h (38,874 kg / h)

If the liquid refrigerant is subcooled to a temperature of 90°F, (32.2°C), then

h3=h4= 10.409 + 0.26851(90) + 0.0001479(90)2+ 5.3429 X 10-7(90)3

= 10.409 + 24.166 + 1.198 + 0.389 = 36.16 Btu/ lb

Refrigeration effect is then increased to

qrf = 107.72 – 36.16 = 71.56 Btu/ lb (166 kJ/kg)

Also COPref is increased to

COPref= 71.56 / 10.024 = 7.14

Since 1 ton = 200 Btu/min and 1 hp = 42.41 Btu/min, electric power input to the compressor Pin

without subcooling is

Pin= (500 X 200) / (42.41 X 6.98) = 337.8 hp (252 kW)

With subcooling,

Pin, s = (500 X 200) / (42.41 X 7.14) = 330.2 hp (246 kW)

Savings in electric energy are calculated as

(337.8 – 330.2) / 337.8 = 0.022, or 2.2%

9.12 MULTISTAGE VAPOR COMPRESSION SYSTEMS

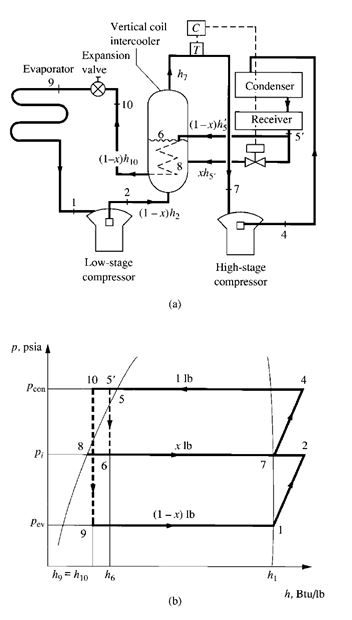

When a refrigeration system uses more than single-stage compression process, it is called a multistage

system (as shown in Fig. 9.7), and may include the following:

- A high-stage compressor and a low-stage compressor

- Several compressors connected in series

- Two or more impellers connected internally in series and driven by the same motor or prime

mover, as shown in Fig. 9.7

- A combination of two separate refrigeration systems

The discharge pressure of the low-stage compressor, which is equal to the suction pressure of the

high-stage compressor, is called the interstage pressure.

The reasons for using a multistage vapour compression system instead of a single-stage system

are as follows:

- The compression ratio Rcom of each stage in a multistage system is smaller than that in a singlestage

unit, so compressor efficiency is increased. Compression ratio Rcom is defined as the ratio

of the compressor’s discharge pressure pdis, psia (kPa abs.), to the suction pressure at the compressor’s

inlet psuc, psia (kPa abs.), or

Rcom = pdis / psuc (9.27)

- Liquid refrigerant enters the evaporator at a lower enthalpy and increases the refrigeration effect.

- Discharge gas from the low-stage compressor can be desuperheated at the interstage pressure.

This results in a lower discharge temperature from the high-stage compressor than would be

produced by a single-stage system at the same pressure differential between condensing and

evaporating pressures.

- Two or three compressors in a multistage system provide much greater flexibility to accommodate

the variation of refrigeration loads at various evaporating temperatures during part-load operation.

The drawbacks of the multistage system are higher initial cost and a more complicated system

than that for a single-stage system.

Compound Systems

Multistage vapour compression systems are classified as compound systems or cascade systems.

Cascade systems are discussed in a later section.

A compound system consists of two or more compression stages connected in series. For

reciprocating, scroll, or screw compressors, each compression stage usually requires a separate

compressor. In multistage centrifugal compressors, two or more stages may be internally compounded

by means of several impellers connected in series.

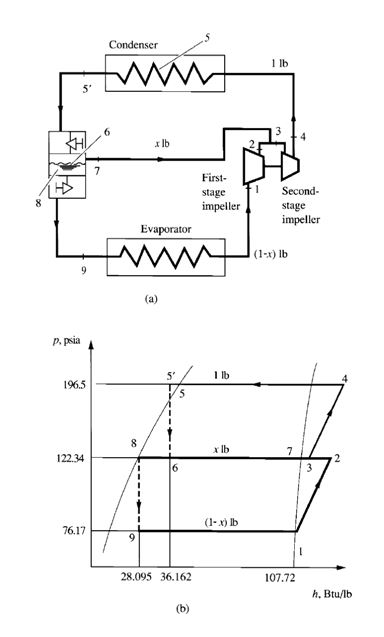

FIGURE 9.7 Two-stage compound system with a flash cooler: (a)

schematic diagram; (b) refrigeration cycle.

Interstage Pressure

Interstage pressure is usually set so that the compression ratio at each stage is nearly the same for

higher COPs. For a two-stage compound system, interstage pressure pi, psia (kPa abs.), can be

calculated as

(9.28)

where pcon= condensing pressure, psia (kPa abs.)

pev= evaporating pressure, psia (kPa abs.)

For a multistage vapour compression system with z stages, the compression ratio Rcom for each stage

can be calculated as

(9.29)

Flash Cooler and Intercooler

In compound systems, flash coolers are used to subcool liquid refrigerant to the saturated temperature

corresponding to the interstage pressure by vaporizing part of the liquid refrigerant. Intercoolers

are used to desuperheat the discharge gas from the low-stage compressor and, more often, to

subcool also the liquid refrigerant before it enters the evaporator.

9.13 TWO-STAGE COMPOUND SYSTEM WITH

A FLASH COOLER

Flow Processes

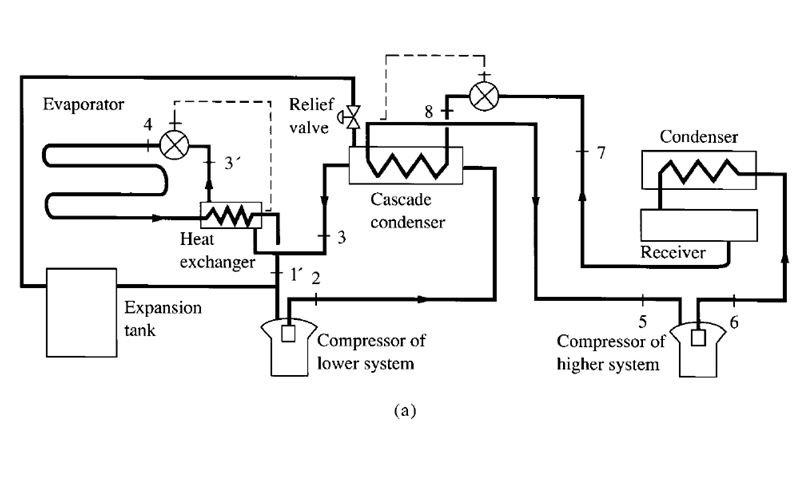

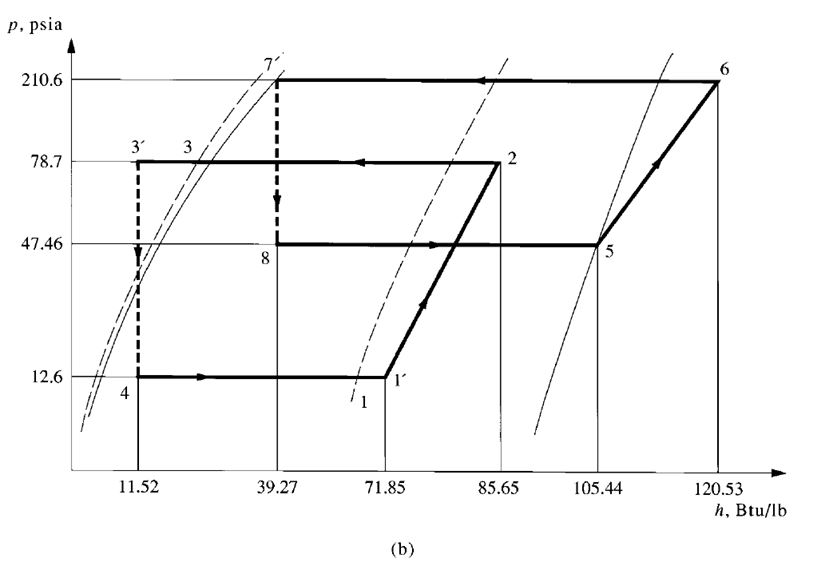

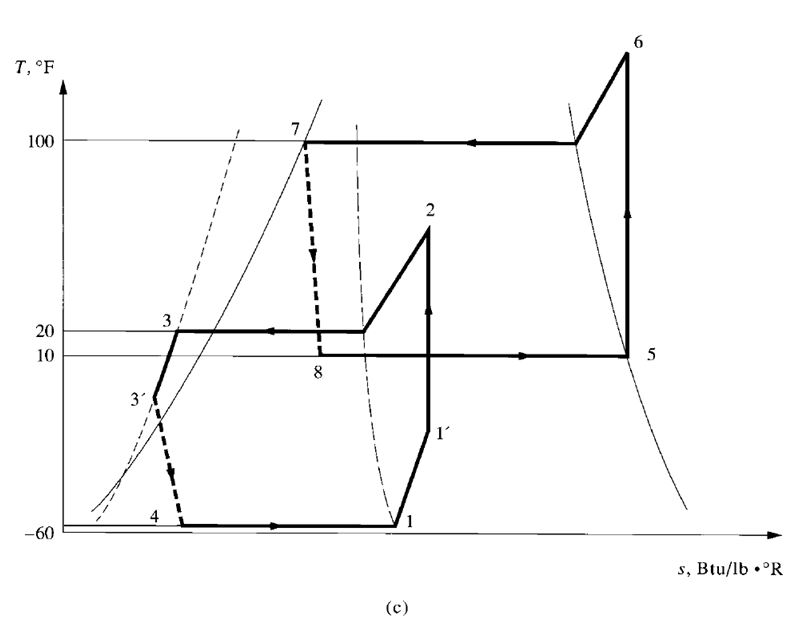

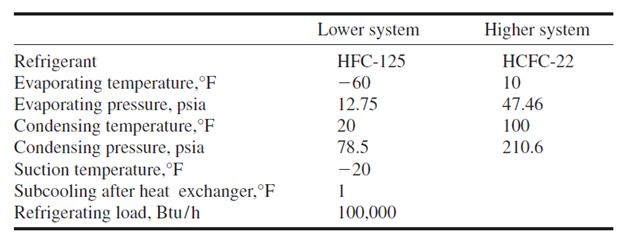

Figure 9.7a is a schematic diagram of a two-stage compound system with a flash cooler, and Fig. 9.7b

shows the refrigeration cycle of this system. Vapour refrigerant at point 1 enters the first-stage impeller

of the centrifugal compressor at the dry saturated state. It is compressed to the interstage pressure pi at

point 2 and mixes with evaporated vapour refrigerant from the flash cooler, often called an economizer.

The mixture then enters the second-stage impeller at point 3. Hot gas, compressed to condensing pressure

pcon, leaves the second-stage impeller at point 4. It is then discharged to the condenser, in which

the hot gas is desuperheated, condensed, and often subcooled to liquid state at point 5_. After the condensing

process, the subcooled liquid refrigerant flows through a throttling device, such as a float

valve, at the high-pressure side. A small portion of the liquid refrigerant flashes into vapour in the flash

cooler at point 7, and this latent heat of vaporization cools the remaining liquid refrigerant to the

saturation temperature corresponding to the interstage pressure at point 8. Inside the flash cooler, the

mixture of vapour and liquid refrigerant is at point 6. Liquid refrigerant then flows through another

throttling device, a small portion is flashed at point 9, and the liquid-vapour mixture enters the evaporator.

The remaining liquid refrigerant is vaporized at point 1 in the evaporator. The vapour then flows to

the inlet of the first-stage impeller of the centrifugal compressor and completes the cycle.

Fraction of Evaporated Refrigerant in Flash Cooler

In the flash cooler, out of 1 lb of refrigerant flowing through the condenser, x lb of it cools down the

remaining portion of liquid refrigerant (1 –x) lb to saturated temperature T8 at interstage pressure

- pi. Because h5‘ is the enthalpy of the subcooled liquid refrigerant entering the flash cooler, h6 is the

enthalpy of the mixture of vapour and liquid refrigerant after the throttling device, for a throttling

process, h5‘=h6. Enthalpies h7 and h8 are the enthalpies of the saturated vapour and saturated

liquid, respectively, at the interstage pressure, and h9 is the enthalpy of the mixture of vapour and

liquid refrigerant leaving the flash cooler after the low-pressure side throttling device. Again, for a

throttling process, h8=h9.

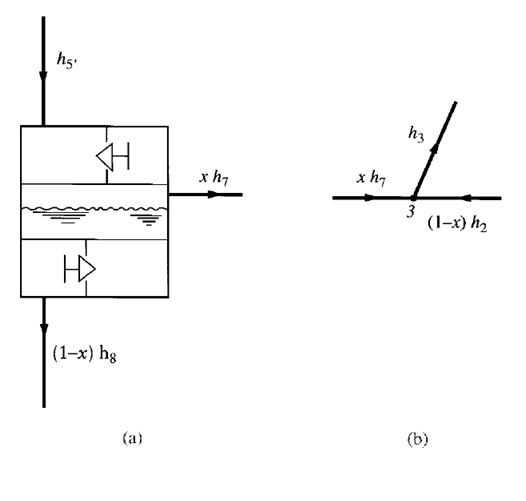

FIGURE 9.8 Heat balance of entering and leaving refrigerants in a

flash cooler and at the mixing point: (a) in the flash cooler; (b) at the

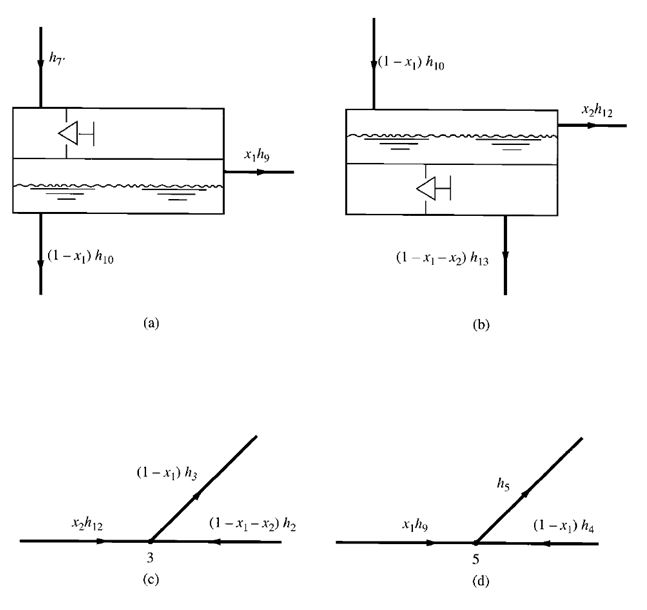

mixing point 3 before entering the second-stage impeller

If the heat loss from the insulated flash cooler to the ambient air is small, it can be ignored. Heat

balance of the refrigerants entering and leaving the flash cooler, as shown in Fig. 9.8a, gives

Sum of heat energy of refrigerant entering flash cooler

= Sum of heat energy of refrigerant leaving flash cooler

that is,

h5′ =xh7+ (1 –x)h8

The fraction of liquid refrigerant evaporated in the flash cooler x is given as

(9.30)

The fraction x also indicates the quality, or dryness fraction, of the vapour and liquid mixture in the

flash cooler at the interstage pressure.

Enthalpy of Vapour Mixture Entering Second-Stage Impeller

Ignoring the heat loss from mixing point 3 to the surroundings, we see that the mixing of the

gaseous refrigerant discharged from the first-stage impeller at point 2 and the vaporized refrigerant

from the flash cooler at point 7 is an adiabatic process. The heat balance at the mixing point before

the second-stage impeller, as shown in Fig. 9.7b, is given as

h3= (1 –x)h2+xh7 (9.31)

where

h2= enthalpy of gaseous refrigerant discharged from first-stage impeller, Btu/ lb (kJ /kg)

h3= enthalpy of mixture at point 3, Btu/ lb (kJ /kg)

h7= enthalpy of saturated vapor refrigerant from flash cooler at point 7, Btu/ lb (kJ /kg)

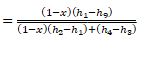

COPref= qrf / Win

Coefficient of Performance

For 1 lb (kg) of refrigerant flowing through the condenser, the amount of refrigerant flowing

through the evaporator is (1 – x) lb (kg). The refrigeration effect qrfper lb (kg) of refrigerant flowing

through the condenser, Btu / lb, (kJ/ kg), can be expressed as

qrf= (1 – x)(h1 – h9) (9.32)

where

h1 = enthalpy of saturated vapour leaving evaporator, Btu / lb (kJ /kg)

h9 = enthalpy of refrigerant entering evaporator, Btu / lb (kJ /kg)

Total work input to the compressor (including the first- and second-stage impeller) Win per lb (kg)

of refrigerant flowing through the condenser, Btu / lb (kJ / kg), is

Win = (1 – x)(h2 – h1) + h4 – h3 (9.33)

where h4 = enthalpy of the hot gas discharged from the second-stage impeller, Btu/ lb (kJ / kg). The

coefficient of performance of the two-stage compound system with a flash cooler COPref is

_

(9.34)

(9.34)

The mass flow rate of refrigerant at the condenser r, lb/h (kg/ s), is

(9.35)

(9.35)

where Qrc = refrigeration capacity, Btu /h (W).

In a two-stage compound system with a flash cooler, a portion of the liquid refrigerant is flashed

into vapour going directly to the second-stage suction inlet, so less refrigerant is compressed in

the first-stage impeller. Furthermore, the remaining liquid refrigerant is cooled to the saturated

temperature corresponding to the interstage pressure, which is far lower than the subcooled liquid

temperature in a single-stage system. The increase in refrigeration effect and the drop in compression

work input lead to a higher COPref than in a single-stage system.

Although the initial cost of a two-stage compound system is higher than that for a single-stage

system, the two-stage compound system with a flash cooler is widely used in large central hydronic

air conditioning systems because of the high COPref.

Example 9.2. For the same 500-ton (1758-kW) centrifugal vapour compression system as in

Example 9.1, a two-stage compound system with a flash cooler is used instead of a single-stage

centrifugal compressor. Vapor refrigerant enters the first-stage impeller at a dry saturated state, and

the subcooled liquid refrigerant leaves the condenser at a temperature of 90°F (32.2°C). Both

compression processes at the first-stage impeller and the second-stage impeller are assumed to be

isentropic. Evaporating pressure is 76.17 psia (525kPa abs.), and the condensing pressure is 196.5

psia (1355 kPa abs.). Other conditions remain the same as in Example 9.1. Calculate

- The fraction of liquid refrigerant vaporized in the flash cooler

- The refrigeration effect per lb (kg) of refrigerant flowing through the condenser

- The total work input to the compressor

- The coefficient of performance of this refrigerating system

- The mass flow rate of refrigerant flowing through the condenser

- The percentage of saving in energy consumption compared with the single-stage vapor compression

System

Solution

- Based on the data calculated in Example 9.1, enthalpy of vapour refrigerant entering the firststage

impeller h1= 107.72 Btu/lb and the enthalpy of the subcooled liquid refrigerant leaving

the condenser h5′= 36.162 Btu/ lb, as shown in Fig. 9.6b. From Eq. (9.28) and the given data,

the interstage pressure can be calculated as

From the Table of Properties of Saturated Liquid and Vapour for HCFC-22 in ASHRAE Handbook

1989, Fundamentals, for pi= 122.34 psia, the corresponding interstage saturated temperature Tiin

the two-phase region is 63.17°F.

From Eq. (9.20), the enthalpy of liquid refrigerant at saturated temperature 63.17°F is

h8=h9= 10.409 + 0.26851(63.17) + 0.00014794(63.17)2+ 5.3429(63.17)3

= 10.409 + 16.961 + 0.59 + 0.135 = 28.095 Btu/ lb

Also, from Eq. (9.21), the enthalpy of the saturated vapour refrigerant at a temperature of 63.17°F is

h7 = 104.465 + 0.098445(63.17) – 0.0001226(63.17)2– 9.861 X 10-7(63.17)3

= 104.465 + 6.219 – 0.489 – 0.249 = 109.946 Btu/ lb

Then, from Eq. (9.30), the fraction of vaporized refrigerant in the flash cooler is

X = (h5 – h8) / (h7 – h8)

= (36.162 – 28.095) / (109.946 – 28.095) = 0.09856

- From Eq. (9.32), the refrigeration effect is

qrf = (1 –x)(h1–h9) = (1 – 0.09856)(107.72 – 28.095)

= 71.78 Btu/ lb (167 kJ/kg)

From Eq. (9.22), the enthalpy differential h2–h1 corresponding to a saturated temperature differential

Ts2 –Ts1= 63.17 – 35 = 28.17°F in the two-phase region is

h2 –h1=-0.18165 + 0.21502(28.17) – 0.0012405(28.17)2+ 8.1982 – 10X 6(28.17)3

=-0.182 + 6.057 – 0.984 + 0.183 = 5.074 Btu/ lb

Similarly, from Eq. (9.22), the enthalpy differential h4–h3 corresponding to a saturated temperature

differential Ts–Ti= 95 – 63.17 = 31.83°F is

h4 –h3=-0.020 + 0.16352(31.83) – 0.00035106(31.83)2+ 1.9177 X 10-6(31.83)3

=-0.020 + 5.205 – 0.356 + 0.062 = 4.891 Btu/ lb

Then, from Eq. (9.33), the total work input to the compressor is calculated as

Win= (1 –x)(h2–h1) +h4–h3

= (1 – 0.09856)(5.074) + 4.891 = 9.465 Btu/ lb (22.0 kJ /kg)

- The coefficient of performance of this two-stage compound system is

COPref = (qrf / win) = (71.78 / 9.465) = 7.58

The mass flow rate of refrigerant flowing through the condenser can be evaluated as

rc / qrf = 500*12000 / 71.78 = 83,588 lb / h (37,916 kg / h)

- From the results in Example 9.1, the power input to the single-stage system is 330.2 hp. The

power input to the two-stage compound system is

Pin = (500*200) / (42.41*7.58) = 311.1 hp (232 kW)

Energy saving compared with the single-stage system is calculated as

= (330.2 – 311.1) / 330.2 = 0.058, or 5.8%

9.14 THREE-STAGE COMPOUND SYSTEM WITH

A TWO-STAGE FLASH COOLER

To reduce the energy consumption of refrigeration systems in air conditioning, the three-stage compound

system with a two-stage flash cooler became a standard product in the 1980s. Fig. 9.9 shows

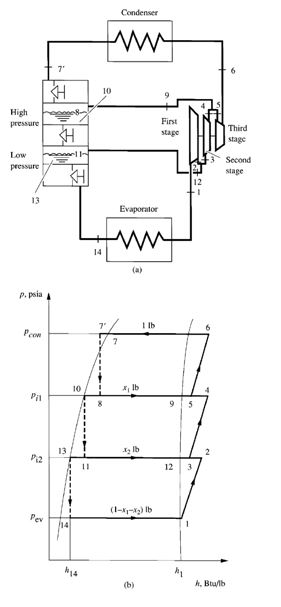

the schematic diagram and refrigeration cycle of this system.

Flow Processes

In Fig. 9.9, vapour refrigerant enters the first-stage impeller of the centrifugal compressor at a dry

saturated state, point 1. After the first-stage compression process, at point 2, it mixes with the vaporized

refrigerant coming from the low-pressure flash cooler at point 12. At point 3, the mixture

enters the second-stage impeller. After the second-stage compression process at point 4, it mixes

again with vaporized refrigerant from the high-pressure flash cooler at point 9. The mixture, at

point 5, is then compressed to the condensing pressure in the third-stage impeller. At point 6, the